| Molybdenum Disilicide Nanopowder | |

| Product No | NRE-5162 |

| CAS No. | 12136-78-6 |

| Formula | MoSi2 |

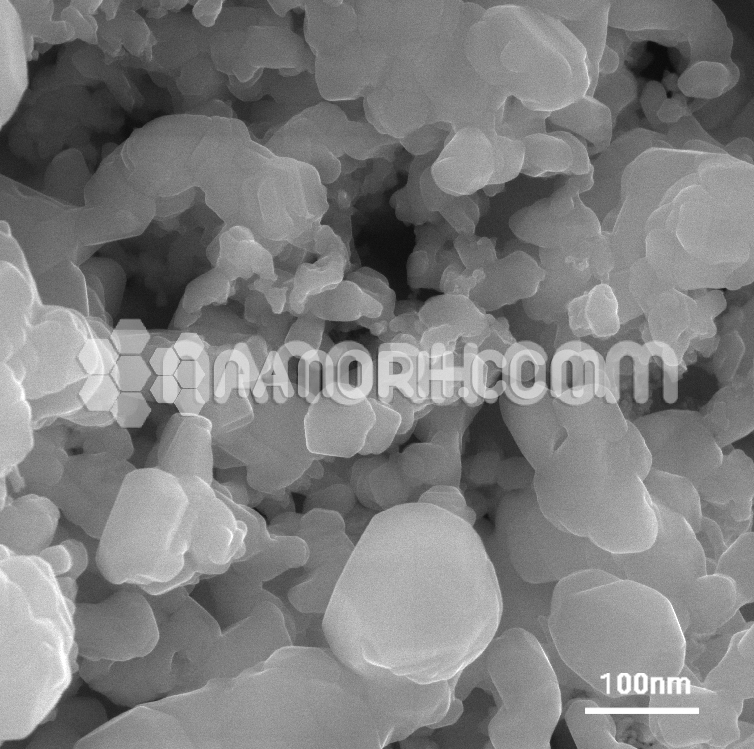

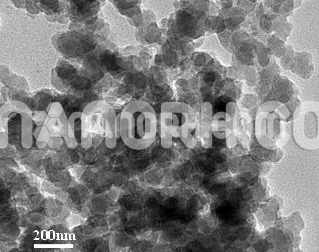

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray Black |

| Molecular Weight | 152.111 g/mol |

| Density | 6.26 g/cm³ |

| Melting Point | 2,030 °C |

| Boiling Point | NA |

Molybdenum Disilicide Nanopowder

Molybdenum disilicide (MoSi2 or molybdenum silicide), an intermetallic compound a molybdenum silicide, and A refractory primary use in ceramic ad heating elements. It has a Moderate density, a melting point of e, and 2030 ° C electrically conductive. Ad high-temperature passivation layer forms silicon dioxide which protects it gives further oxidation. It is a gray metalized material with a tetragonal crystal structure (alpha modification); Its beta modification is hexagonal and unstable. E In most insoluble ACIDS but soluble in hydrofluoric acid and nitric acid. WHILE MoSi2 has an excellent oxidation resistance and a high-temperature module for young people higher than 1000 ° C, and more fragile at low temperatures. Furthermore, at over 1200 ° C resistance is lost. These properties limit the use of eating structural material but can be combined to use it to eat composite material. Molybdenum disilicide The Materials and I based Are of MoSi2 generally Sintering Products. The plasma can be sprayed to used to produce monolithic forms site and dense composite; The product Material in PU mode contain a percentage of β-MoSi2 because of its rapid cooling. The elements may be heated in molybdenum disilicide to be used at the end of the temperature at 1800 ° C, in which the laboratories used are electric ovens and in the production of the production environments of glass, steel, electronics, ceramics and in the treatment of thermal materials. Although fragile elements, they can function at high electrical power without aging and the parrot resistivity does not increase with time functioning. The SUA Maximum operating temperature MUST be reduced to low content in atmospheres with oxygen due to the passivation layer of the decomposition has. Other ceramic materials used to heat elements are, e.g. Silicon carbide, barium titanate, and lead titanate composites. Molybdenum disilicide is made in microelectronics as a contact material. E On the lines Often used to eat polysilicon bypass to increase its conductivity and increase the speed of the signal.