| Molybdenum Disulfide MoS2 Nanoparticles | |

| Product No | NRE-5163 |

| CAS No. | 1317-33-5 |

| Formula | MoS2 |

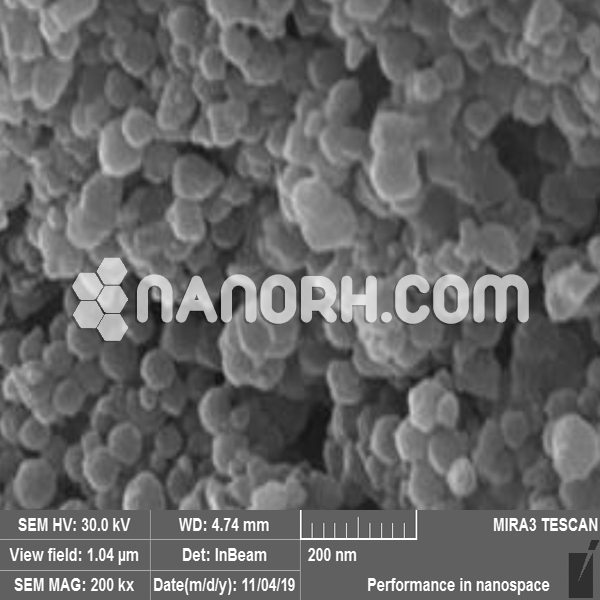

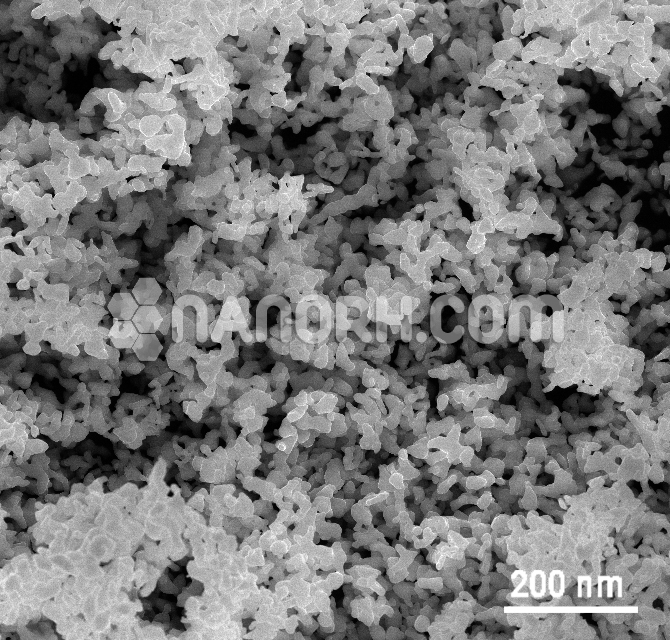

| APS | <135 nm (Can be Customized) |

| Purity | 99.9% |

| Color | Greyish Black |

| Molecular Weight | 160.07 g/mol |

| Density | 5.06 g/cm3 |

| Melting Point | 2375°C |

| Boiling Point | NA |

Molybdenum Disulfide MoS2Nanoparticles Feature:

This item is a glossy dull dark powder, thickness 4.8, softening point 1185 °C, 450 °C sublimation, Mohs hardness of 1 to 1.5. Under ordinary conditions, the grinding coefficient of 0.03 ~ 0.05 and great synthetic solidness and warm soundness. Broken down in water Regia and concentrated sulfuric corrosive, insoluble in water and weaken corrosive; No broad compound response with the metal surface; Not dissolve the elastic material; Can be utilized for preparing and capacity of extra parts; Maintenance oil bond; can frame a very proficient dry greasing up film; Is less wear and grating decrease innovation.

Molybdenum Disulfide Nanoparticles as a strong ointment, one reason is of its layered structure, between layers of sulfur molecules joined with feeble simple to-slide and indicated great contact decreasing impact; the second reason, presentation sulfur particles of the precious stone surface on the metal surface have an extremely solid attachment to shape an exceptionally strong film, in this manner grease is better than other general-greasing up materials. As contrasted and common molybdenum disulfide, Nano molybdenum disulfide has numerous amazing properties, for example, phenomenal rubbing, expansive dynamic surface zone, more adsorption limit, high reactivity, synergist properties, particularly the execution of reactant hydrogenation desulfurization more, can be utilized to get ready extraordinary materials, synergist materials, and gas stockpiles. In nano-layers of molybdenum disulfide into alternate gatherings after the development of intercalated nano-composite materials have numerous magnificent physical properties, (for example, light, power, attraction, catalysis, oil, and different capacities). With MoS2 molecule estimate winds up plainly littler, it is appended to the surface of the rubbing material and the scope has expanded altogether, hostile to wear grating properties has likewise been essentially progressed.

Molybdenum Disulfide Nanoparticles Application:

1 in oil applications: not exclusively can enhance the oil’s biggest non-card nibble stack, yet in addition can decrease wear and enhance the grating properties, the system for the nano than the normal molybdenum disulfide is more inclined to contact and concoction response the arrangement of sulfur and molybdenum-rich greasing up the film, the sky antiwear, molybdenum disulfide to lessen rubbing and wear instrument totally not the same as the oil, the high vacuum can keep on maintaining its phenomenal protection from erosion and wear properties, its principal application in hard to look after hardware, for example, space vehicles, satellites.

2 in the composite application: PS/MoS2 nanocomposites, will have a specific conductivity of MoS2 as a conductive filler to enhance the polystyrene (PS) of the electrical properties, it has a specific limit, however, won’t change the counter static the protection.

3 in respect to the general molybdenum disulfide, nano molybdenum disulfide can fundamentally build the number of surface iotas, the arrangement of more sulfur opening, to higher synergist action and selectivity can be utilized as a substantial oil change, oil refining hydrogenation impetus of high movement, nano-MoS2 during the time spent methanation of carbon monoxide as an impetus with high selectivity and reactivity. Molybdenum Disulfide Nanoparticles is an impetus for coal liquefaction.