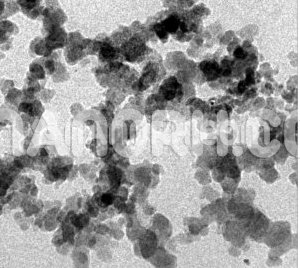

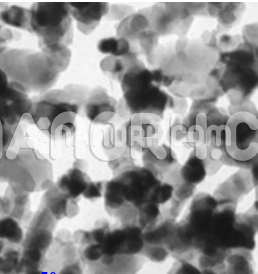

Nickel Chromium Cobalt Alloy Nanopowder/Nanoparticles (Ni:Cr:Co, 99.9%, <80nm)

Nickel Chromium Cobalt Alloy Nanoparticles

| Nickel Chromium Cobalt Alloy Nanopowder | |

| Product No | NRE- 2034 |

| CAS No. | 7440-02-0 / 7440-47-3 / 7440-48-4 |

| Formula | NiCrCo |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey |

| Molecular Weight | 169.6227 g/mol |

| Density | 8.027-9.7 g/cm3 |

| Melting Point | 1310-1370 °C |

| Boiling Point | NA |

Nickel Chromium Cobalt Alloy Nanopowder

As is generally known in the art, nickel-chromium-cobalt-based alloys Nanopowder often contain precipitation hardening elements, such as titanium and aluminum, for strengthening purposes. Said alloys develop, in suitable heat treatment, a high level of resistance to stress rupture at high temperature and are widely used in applications where both high pressures and high temperatures are encountered, the motor rotor blades of which are illustrative. gas turbine. However, due to the impure fuels used in terrestrial gas turbines, problems related to incomplete combustion and sulphuration attacks arise. Operation in marine environments and others that contain chloride has also resulted in severe corrosion problems in the past. One way to improve the level of corrosion resistance is to increase the chromium content, as described, which relates to alloys containing at least 27% chromium. However, nickel-chromium-cobalt-based alloys Nanopowder suffer from the disadvantage with respect to the level of resistance that can be obtained without problems of instability due to sigma formation and embrittlement after prolonged service. In addition, they generally refer to forged alloys, which are of limited utility for the manufacture of turbine blades having complex cooling passages. Therefore, the invention is directed to the task of developing an alloy possessing, in the form of a case, a high level of high-temperature resistance together with good resistance to corrosion in environments containing sulfur and chloride.