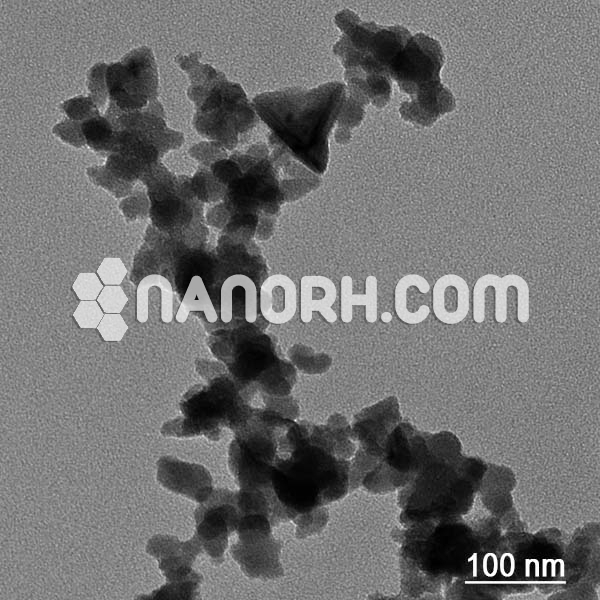

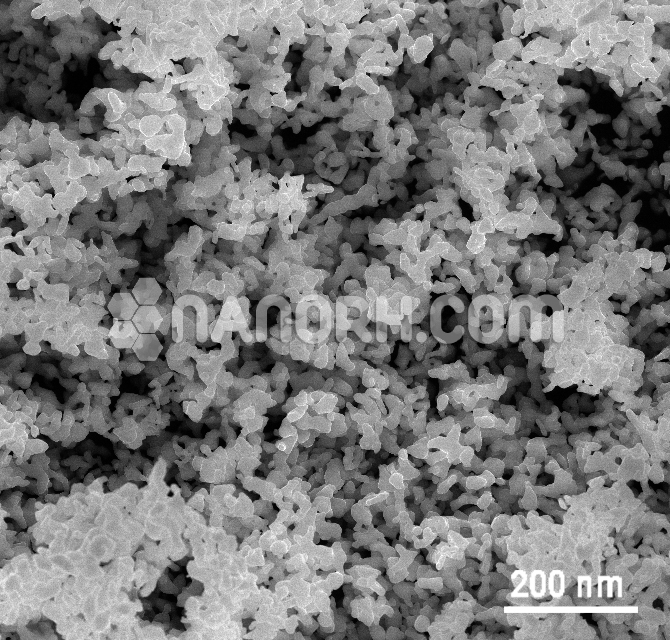

| Silicon Carbide Nanoparticles | |

| Product No | NRE-5197 |

| CAS No. | 409-21-2 |

| Formula | SiC |

| APS | <65nm (Can be Customized) |

| Purity | 99.9% |

| Color | bluish-black |

| Molecular Weight | 40.0962 g/mol |

| Density | 3.16 g/cm³ |

| Melting Point | 2830°C |

| Boiling Point | NA |

Silicon Carbide Nanoparticles for Sale

1. Superior Quality refractory material

Silicon Carbide Nanoparticles for Sale is particularly utilized material for cleaning grating; Ceramic course; Ceramic motor parts; Grinding wheels; Textile pottery; High-recurrence earthenware production; Hard plate and a help for multichip modules; High-temperature and high-control semiconductors; High-temperature clay heading; High-temperature liquid transport parts; High hardness crushing materials; High-temperature fixing valves; High-temperature shower spouts; Integrated circuit substrate; Catalyst bolster; Mirror or coatings for outrageous bright condition; Nanocomposites (e.g., Si3N4/SiC, SiC/polymer); Resistance warming components; Strengthening materials for Al, Al2O3, Mg, and Ni…..

2. Utilized as new material to fabricate high-strength nylon alloys

Silicon Carbide Nanoparticles for Sale has great scattering and similarity in polymer composites. The high-quality nylon combination has a superior elasticity which is 10% higher than the normal PA6, and the wearing protection expanded by in excess of 2.5 times. Silicon carbide nanopowder is for the most part utilized for creating protected followed vehicles polymer parts, directing parts, material apparatus, mining hardware, linings, train parts which can accomplish densification at a lower temperature sintering.

3. Applied for wear protection of uncommon designing plastics, polyether ether ketone (PEEK)

After surface treatment with coupling operator, Silicon Carbide Nanoparticles for Sale can extraordinarily enhance and improve the wear resistance of PEEK with the dose of around 10%, (The scraped area of PEEK loaded with micron silicon carbide is for the most part pear cut and rough wear, The scraped area of PEEK loaded with nanoscale silicon carbide is principally slight wear with cement exchange wear )

4. Silicon Carbide Nanoparticles for Sale in the elastic tire

Include a specific measure of nano silicon carbide does not change the first paste recipe adjustment, without trading off its unique execution and quality under the introduce of the wear protection can be expanded by 15% – 30%. similarly, the 20-nanometer silicon carbide utilized as a part of the elastic roller, printer fuser film wear, warmth, temperature and other elastic items. Nano SiC composite nickel and other metal surfaces: nanoscale particles of blended particles, nickel network metal, the metal surface to frame a high density, binding great electrodeposited composite covering, the metal surface with super-hard (wear) and antifriction (greasing up) high-temperature characteristics. The microhardness of the composite covering significantly enhance the wear protection is expanded by 3-5 times, 2-4 times the administration life of the covering and substrate authoritative by 30-40%, scope capacity, uniform covering, smooth, point by point. Different applications: elite auxiliary pottery, (for example, rocket spouts, atomic industry, and so forth.), the engrossing material, against wear oil, superior brake cushions, high hardness and wear-safe powder coating, ceramic composite improved toughening.