Zinc Oxide (ZnO) Nanopowder in Ethanol Dispersion (ZnO Ethanol Dispersion, 40wt%, 30-40 nm)

Rubber tires: zinc oxide dispersion for silicon rubber, boots, rubber gloves and other labor products, it can greatly extend the life of the products, and improve their appearance and color. It is irreplaceablein by other traditional carbon black surfactant in the use of clear or colored rubber products. Zinc oxide dispersion can also greatly improve products wear resistance and sealing effect.

| Zinc Oxide (ZnO) Nanopowder in Butyl Acetate Dispersion | |

| Product No | NRE-23062 |

| CAS No. | 1314-13-2 |

| Formula | ZnO |

| Molecular Weight | 81.38 g/mol |

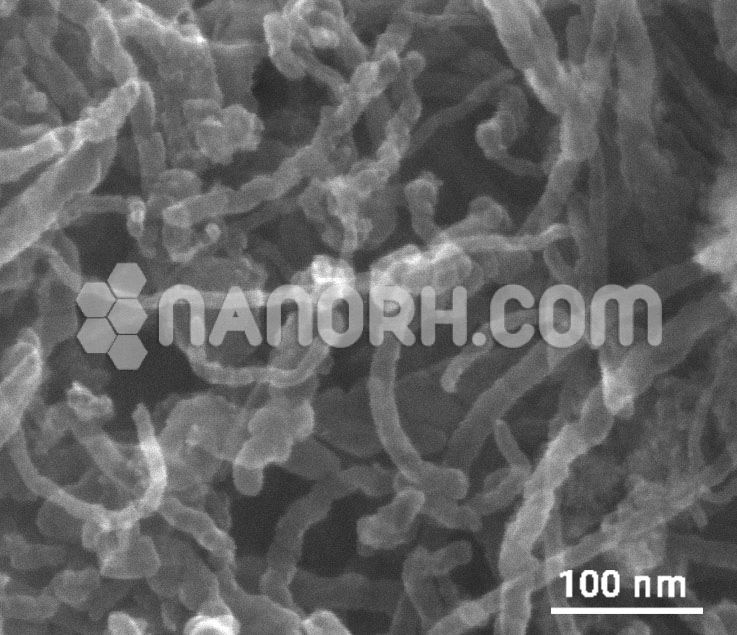

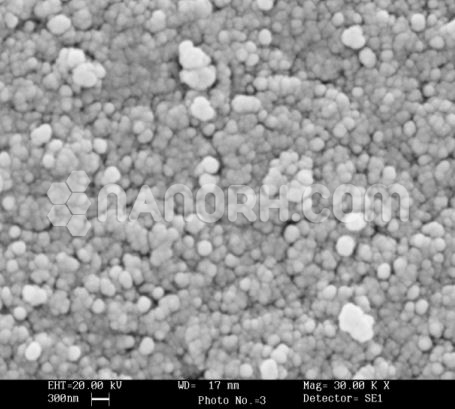

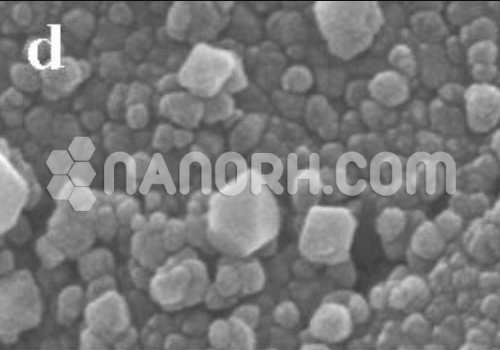

| APS | <40nm (can be customized) |

| Purity | 99.5% |

| Density | 5.61 g/cm³ |

| Color | White liquid |

| Solvent | Ethanol (as per requirement) |

| pH | NA |

Zinc Oxide (ZnO) Nanopowder Dispersion

1. rubber tires: zinc oxide dispersion for silicon rubber, boots, rubber gloves, and other labor products, it can greatly extend the life of the products, and improve their appearance and color. It is irreplaceable by other traditional carbon black surfactants in the use of clear or colored rubber products. Zinc oxide dispersion can also greatly improve products that wear resistance and sealing effect.

2. Paint coating: zinc oxide dispersion can make a coating with UV shielding to absorb infrared rays and sterilization Antifungal and improve paint with stain resistance, resistance to artificial aging, water-alkali resistance, abrasion resistance, hardness and adhesion, and other traditional mechanical properties.

3. Pottery field: sinter temperature can be reduced 40-60 centigrade in pottery.

4. Fibre and textile: effectively screen ultraviolet radiation and infrared ray.

5. Sunproof cosmetics: effective UV-resistance and antibacterial property.

Note:

Nanoparticle dispersions are suspensions of nanoparticles in water. These dispersions can be used as-is or diluted with suitable (compatible) solvents. Nanoparticles in dispersions can sometimes settle upon storage, in which case they can be mixed (shook up) before use…..