Product No: NRE-9081

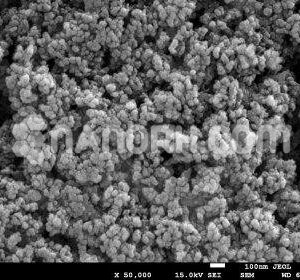

| Nickel-Based fluxed alloy powder | Grade | Chemistry | Size | Hardness |

| NiCrBSiFe Atomized | Ni20A | C:0.1;Si:3;B:1;Cr:1;Fe≤6;Ni:Bal | -150mesh+45um

-106+45um |

20 |

| Ni40A | C:0.3;Si:3;B:2;Cr:10,Fe≤15;Ni:Bal | -150mesh+45um

-106+45um |

40 | |

| Ni45 | C:0.4;Si:3;B:2.6;Cr:12;Fe≤15;Ni:Bal | -150mesh+45um

-106+45um |

45 | |

| Ni60 | Cr:18.5,Si:4.2,Fe:4.2,

B:3.3,C:0.7,Ni:Rem. |

-150mesh+45um

-106+45um |

60 |

Nickel Based Fluxed Alloy Powder

Applications

Welding and Brazing:

One of the primary applications of nickel based fluxed alloy powder is in welding and brazing. The powder is often used to create strong, durable joints between components made of nickel alloys, stainless steel, and other metals. The fluxing agents in the powder ensure that the joint is clean, minimizing oxidation and enhancing the strength and appearance of the weld. These applications are common in the aerospace, automotive, and shipbuilding industries.

Aerospace Industry:

In the aerospace industry, components such as turbine blades, heat exchangers, and engine parts require materials that can withstand extreme temperatures, corrosion, and mechanical stress. NiCrBSiFe are used for high-performance welding and brazing of these components, ensuring the parts maintain their structural integrity and resistance to thermal and chemical degradation.

Chemical Processing and Petrochemical Industries:

are used in the chemical processing and petrochemical industries for welding pipes, vessels, and equipment that come into contact with aggressive chemicals. These alloys are resistant to corrosion and oxidation, making them ideal for manufacturing components for chemical reactors, heat exchangers, and pumps used in these industries.

Marine Industry:

Marine applications often require materials that can withstand the harsh conditions of seawater. NiCrBSiFe are used for welding and brazing marine components such as propellers, engine parts, and hull components.