Highly Conductive Carbon Nanotubes

Effectively improve the electrical conductivity, thermal conductivity and mechanical properties; Effectively enhance tensile strength, hardness and elastic modulus characteristics. Also, Higher electrode conductivity and stronger electrode mechanical strength and adhesive attraction; The product is composed of high electric conductive CNTs and graphene and highly conductive carbon black nanopowder. The carbon black nanoparticles can not only prevent dispersed CNTs and graphene from reagglomerating, but also exhibit synergetic effect with CNTs and graphene.

| Highly Conductive Carbon Nanotubes | |

| Product No | NRE-39018 |

| CAS No. | NA |

| Purity | > 97% |

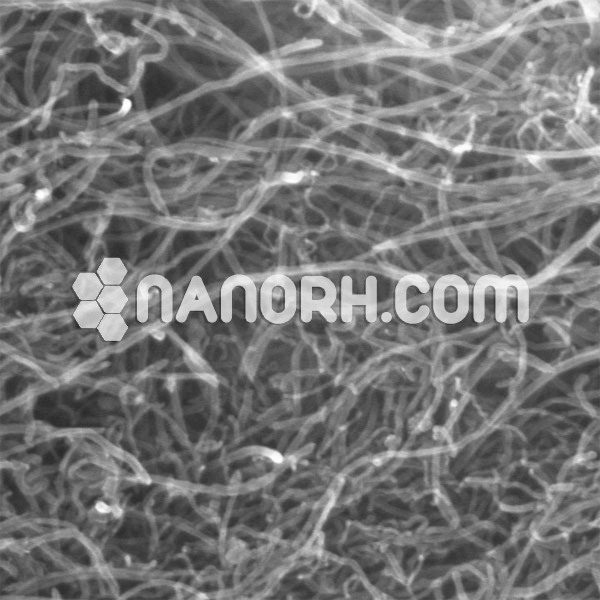

| Average Diameter | >55 nm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | > 60 m2/g (BET) |

| Tap Density | 0.12 g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | >100 s/cm |

Highly Conductive Carbon Nanotubes

Introduction

Carbon Nanotubes carbon nanotubes are cylindrical structures made of graphene sheets rolled into tubes, with carbon atoms arranged in a hexagonal lattice. These nanostructures exhibit exceptional electrical, thermal, and mechanical properties, making them one of the most promising materials for a wide range of advanced applications.

Applications

Electronics and Conductive Materials

Transparent Conductive Films: CNTs are used to create transparent conductive films for displays, touchscreens, and solar cells. Unlike traditional metal-based transparent conductors (like indium tin oxide, or ITO), CNTs offer better flexibility, cost-effectiveness, and environmental sustainability. They are increasingly used in flexible electronics such as wearable devices and smart packaging.

Conductive Inks: CNTs are used in printed electronics to make conductive inks for printing circuits, antennas, and other electronic components directly onto substrates like paper, plastic, or fabric. This application is particularly valuable in the production of flexible electronics and RFID tags.

Interconnects for Microelectronics: In advanced microelectronics, CNTs are being explored as interconnects (wires that connect various parts of an integrated circuit).

Sensors: The high conductivity of CNTs makes them ideal for use in sensors that detect various physical or chemical changes. CNT-based sensors can detect gases, chemicals, and biomolecules, and they are used in applications such as environmental monitoring, medical diagnostics, and smart wearables.

Energy Storage and Supercapacitors

Supercapacitors: CNTs are used in the fabrication of supercapacitors, which are energy storage devices that provide high power density and rapid charge/discharge cycles. Due to their large surface area and conductivity, CNTs help improve the energy storage capacity and efficiency of supercapacitors, making them suitable for applications in electric vehicles (EVs), grid energy storage, and consumer electronics.

Batteries: CNTs are also being utilized to enhance the electrodes of lithium-ion batteries and lithium-sulfur batteries. The high conductivity of CNTs can improve the charge/discharge rate and overall performance of these energy storage systems. They enable faster charging times and higher energy densities, which are crucial for electric vehicles and portable electronics.

Nanostructured Electrodes: CNTs are often incorporated into nanostructured electrodes to enhance performance in lithium-ion and sodium-ion batteries. Their conductivity improves the electron flow, resulting in better overall performance in terms of energy density and cycle life.

Thermal Management

Heat Dissipation: Due to their high thermal conductivity, CNTs are used in thermal interface materials (TIMs) to improve the heat dissipation in high-performance electronic devices like microprocessors, LEDs, and power supplies. CNTs help to efficiently transfer heat from hot spots to heat sinks or cooling systems, improving device longevity and performance.

Thermal Conductive Composites: CNTs are integrated into thermal conductive composites for use in electronic packaging, automotive applications, and energy systems. These composites help manage the thermal load of critical components, reducing the risk of overheating.

Composite Materials

Structural Composites: CNTs are incorporated into polymer composites to enhance their electrical, thermal, and mechanical properties. These CNT-reinforced composites are used in a wide variety of applications, including aerospace, automotive, and construction. The lightweight nature of CNTs makes them ideal for use in applications where reducing weight is critical, such as in aircraft and automobile parts.

Wear-resistant Coatings: CNTs improve the abrasion resistance and durability of coatings and materials, which is useful in industries such as machinery, automotive, and electronics.