AlSi10Mg Alloy Powder For 3D Printing

The main application of 3D printing metal powder;

aerospace

molds

automotive

medical instruments

Military industry

Categories: 3D Printing Metal Powder, Micro Powder

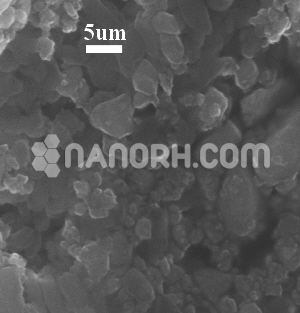

| Product No. | Aluminum Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60002 | NRE-AlSi10Mg | Si 9-11,Mg 0.3-0.5, Al Bal. | 0.05-0.15 | 0.8-1.8 | 15-53 µm, 20-60 µm, 30-80 µm, 45-105 µm, D50 10-15 µm, |

| NRE-AlSi7Mg | Si 6-8,Mg 0.3-0.5, Al Bal. | ||||

| NRE-AlSi12 | Si 11-13, Al Bal. | ||||

| NRE-AlMgScZr | Mg 5, Sc 0.6-0.8, Zr 0.3-0.5, Al Bal. | ||||

| NRE-5052 | Cu 5.8-6.8, Mn 0.2-0.4, Zr 0.1-0.25 Al Bal. | 0.9-1.9 | |||

| NRE-7075 | Mg 1-3, Mn 0.3 Al Bal. | 1.0-2.0 |

AlSi10Mg Alloy Powder For 3D Printing