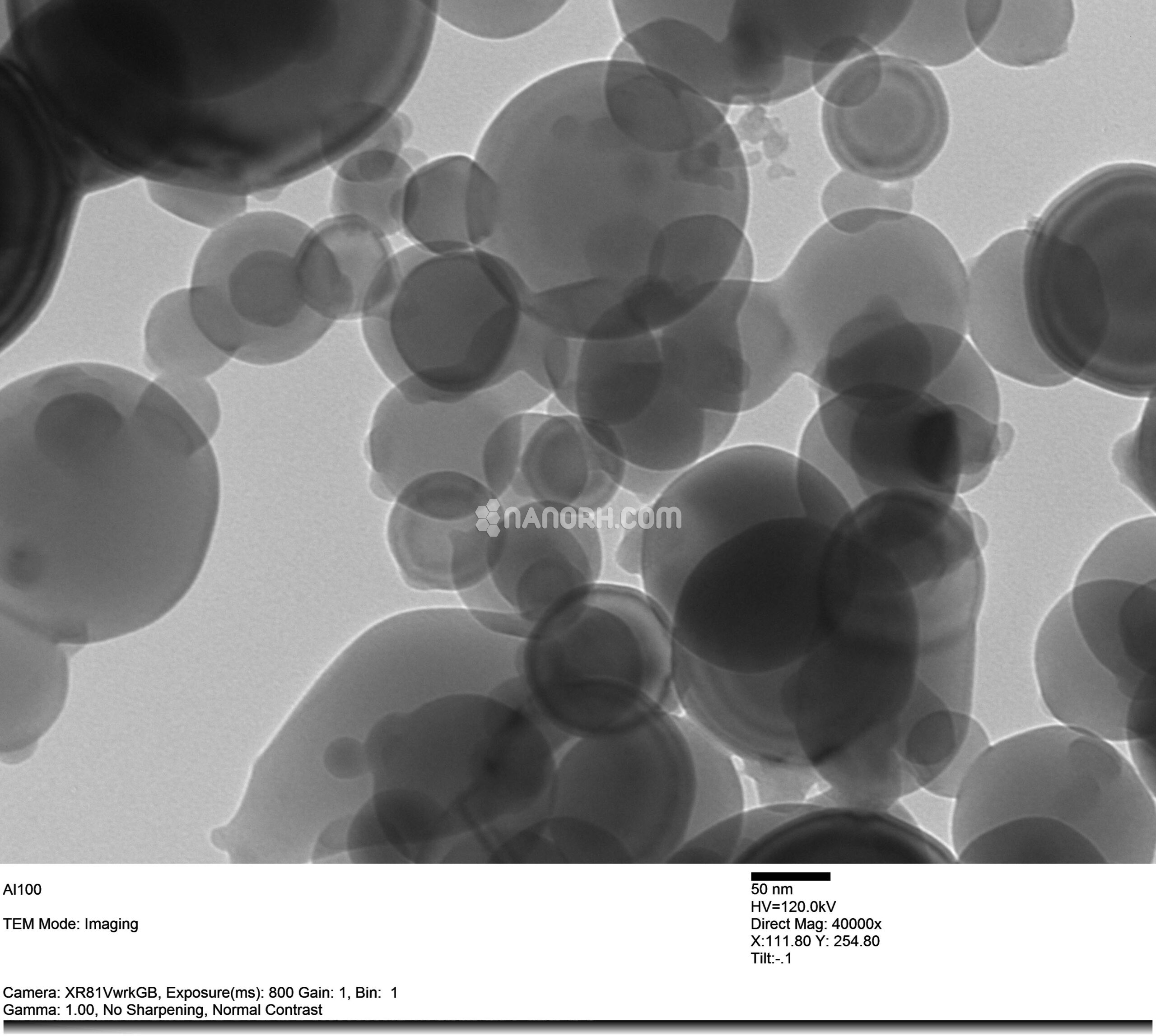

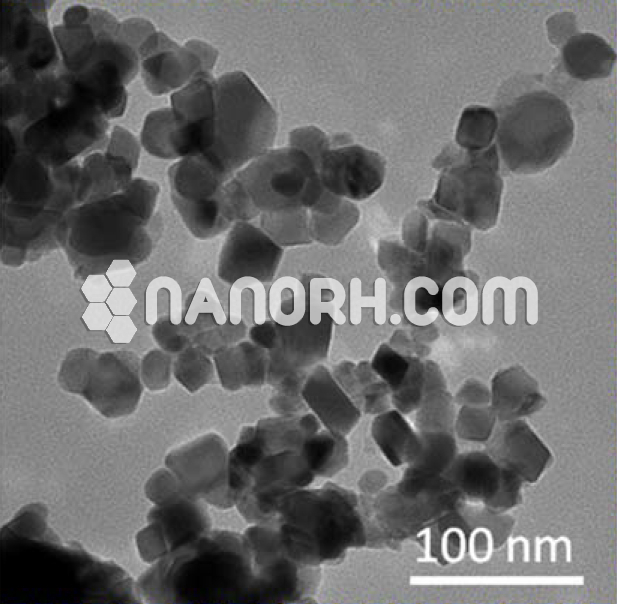

| Aluminium Nanoparticles | |

| Product No | NRE-1001 |

| CAS No. | 7429-90-5 |

| Formula | Al |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Grey |

| Molecular Weight | 26.982 g/mol |

| Density | 2.70 g/cm3 |

| Melting Point | 660.32 °C |

| Boiling Point | 2470 °C |

Aluminium Nanoparticles Application:

Aluminium nanoparticles have a wide range of applications due to their unique properties. Some of the applications of aluminium nanoparticles include:

Catalysis: Al nanoparticles are used as catalysts in various chemical reactions due to their high surface area-to-volume ratio and reactivity. They can be used in catalytic converters, fuel cells, and the production of fine chemicals.

Composite materials: Al nanoparticles can be used to improve the mechanical and thermal properties of composite materials, such as plastics, ceramics, and metals. They can also be used as a reinforcing agent in polymers and composites.

Electronics: Al nanoparticles can be used in electronic applications, such as in the production of conductive inks and coatings, and in the fabrication of electronic components, such as transistors.

Sensors: Al nanoparticles can be used as sensors for detecting gases, chemicals, and other substances. They can also be used in biosensors for detecting biological molecules, such as DNA and proteins.

Energy storage: Al nanoparticles can be used in energy storage applications, such as in the production of batteries and supercapacitors.

Medical applications: Al nanoparticles have potential medical applications, such as in drug delivery systems, cancer therapy, and imaging.

Aluminium nanoparticles, due to their unique properties, find applications in various fields. Here are some notable applications:

Catalysis:

Aluminium nanoparticles serve as effective catalysts in various chemical reactions. Their high surface area and reactivity make them valuable in catalyzing organic reactions.

Energetic Materials:

Aluminium nanoparticles are used in the development of advanced propellants and explosives. Their combustion properties contribute to enhanced energy release.

Fuel Additives:

Adding Al nanoparticles to fuels can improve combustion efficiency and reduce emissions. The nanoparticles act as combustion enhancers, leading to more complete fuel oxidation.

Therapeutics:

In medicine, Al nanoparticles are explored for drug delivery systems. They can be functionalized to carry drugs and target specific cells or tissues, improving drug efficacy and minimizing side effects.

Coatings and Surface Treatments:

Al nanoparticles are used in coatings for surfaces to provide enhanced properties such as corrosion resistance, scratch resistance, and improved adhesion.

Electronic and Photonic Devices:

In the electronics industry, Al nanoparticles are utilized in the fabrication of conductive inks and pastes for printed electronics. They also find applications in optoelectronics and photonics.

Thermal Management:

Due to their high thermal conductivity, Al nanoparticles are incorporated into thermal interface materials. These materials help dissipate heat efficiently in electronic devices, improving their performance and reliability.

Water Treatment:

Al nanoparticles can be employed in water treatment processes. They can remove pollutants through adsorption and catalytic reactions, contributing to the purification of water.

Surface Enhanced Raman Scattering (SERS):

Al nanoparticles are used in SERS applications for highly sensitive molecular detection. The enhanced electromagnetic fields around the nanoparticles amplify the Raman signals of molecules adsorbed on their surfaces.

Anti-microbial Applications:

Al nanoparticles exhibit antimicrobial properties and can be incorporated into coatings or materials to impart antibacterial and antifungal characteristics.

Energy Storage:

Al nanoparticles are investigated for their potential use in energy storage devices, such as batteries and supercapacitors, due to their high surface area and conductivity.

Sensor Technology:

Al nanoparticles are employed in the development of sensors for detecting various analytes. Their unique properties contribute to the sensitivity and selectivity of these sensors.

Additive Manufacturing:

Al nanoparticles can be used in additive manufacturing processes like 3D printing to create lightweight and high-strength components with improved mechanical properties.

Environmental Remediation:

Al nanoparticles are explored for environmental applications, such as the removal of pollutants from air and water through adsorption and catalytic degradation.