| Aluminum Titanium Alloy Sputtering Targets | |

| Product No | NRE-43316 |

| CAS No. | NA |

| Formula | Al-Ti |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

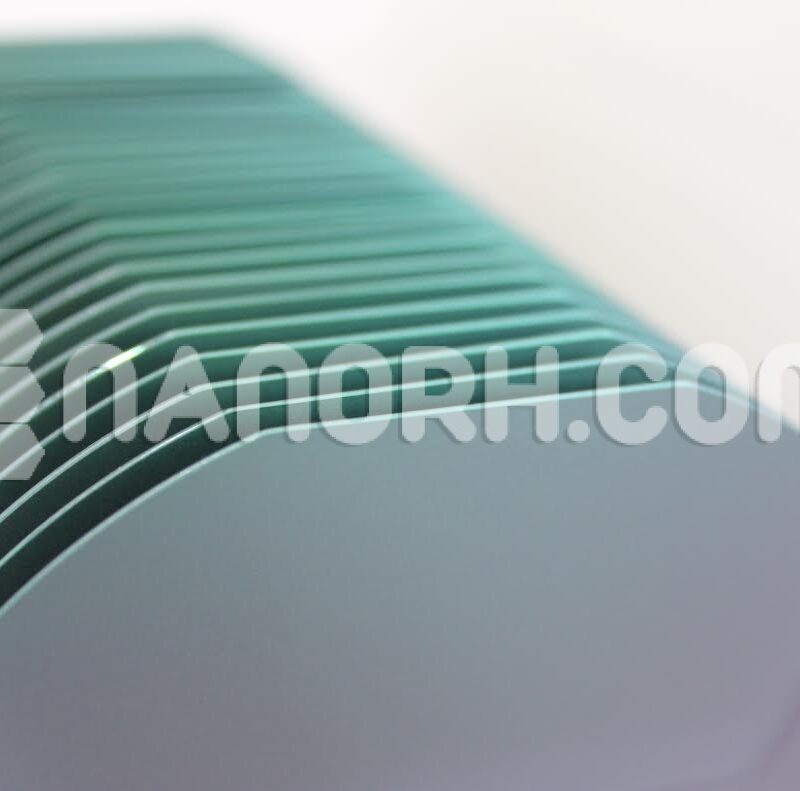

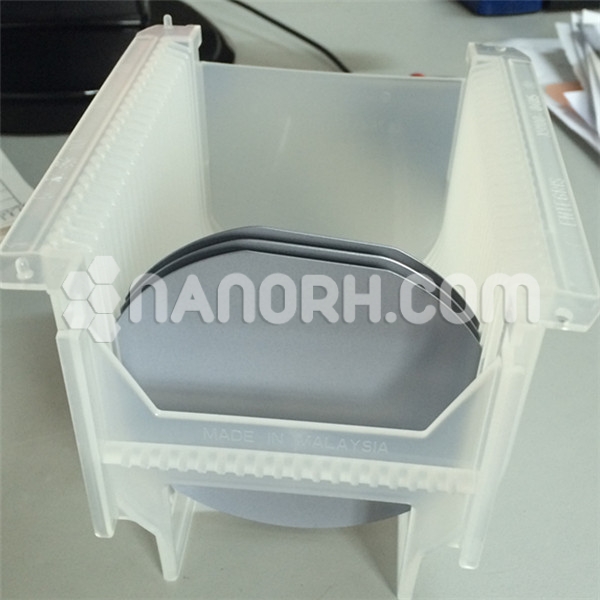

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Aluminum Titanium Alloy Sputtering Targets

Aluminum titanium (Al-Ti) alloy sputtering targets are utilized in the deposition of thin films with unique properties beneficial for various advanced applications. The combination of aluminum and titanium imparts specific characteristics to the sputtered films, making them suitable for a range of high-tech and industrial uses. Here’s a detailed look at the applications and benefits of Al-Ti alloy sputtering targets.

Thin-Film Coatings

Protective Coatings:

Application: Al-Ti alloy films are used as protective coatings on various substrates to enhance wear resistance and durability.

Benefits: Improves surface hardness and resistance to abrasion, corrosion, and oxidation.

Technical Detail: The alloy provides a balance of hardness and toughness, making it suitable for applications requiring enhanced durability under mechanical stress.

Hard Coatings:

Application: Used in the coating of cutting tools, molds, and mechanical parts to improve their hardness and wear resistance.

Benefits: Extends the lifespan of tools and parts by reducing wear and maintaining sharpness and precision.

Technical Detail: The titanium component enhances the hardness and wear resistance of the coating, while aluminum contributes to overall film properties.

Electronics and Semiconductor Devices

Electrodes and Contacts:

Application: Al-Ti films are employed as electrodes and contact layers in semiconductor devices.

Benefits: Provides good electrical conductivity and stability, essential for reliable electronic performance.

Technical Detail: The alloy’s combination of aluminum and titanium offers a conductive and stable material for use in various electronic components.

Barrier Layers:

Application: Used as barrier layers in semiconductor devices to prevent diffusion of materials and maintain device integrity.

Benefits: Helps in maintaining the purity and performance of semiconductor layers by preventing metal diffusion.

Technical Detail: The alloy’s properties make it effective in forming a stable barrier between different materials in semiconductor structures.