| Antimony Sulfide Nanopowder | |

| Product No | NRE-5010 |

| CAS | 1345-04-6 |

| Purity | 99.9% |

| Formula | Sb2S3 |

| APS | <100 nm (Can be Customized) |

| Color | NA |

| Molecular Weight | 339.72 g/mol |

| Density | 4.6 g/mL |

| Melting Point | 550 °C |

| Boiling Point | 1,150 °C |

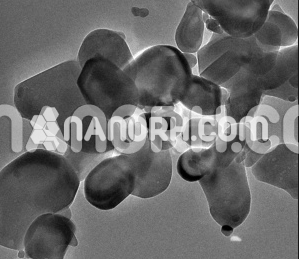

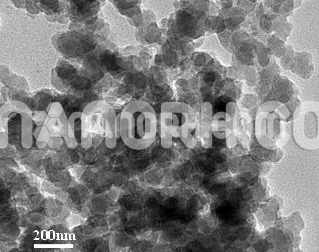

Antimony Sulfide Nanopowder

The Antimony Sulfide Nanopowder have versatile potential applications, such as photovoltaic conversion, optoelectronics, tribology, photo catalysis in response to visible light, etc. Among these applications, photovoltaic material is the most interesting, since Antimony Sulfide Nanopowder has a high absorption coefficient (1.8 × 105 cm-1 at 450 nm) and a relatively narrow optical band gap of 1.6-1 .8 eV, which is adequate for capturing photos of visible light. For photovoltaic application, organic thin-film hybrid solar cells (HSC) are the often studied targets, in which inorganic nanopowder are generally used as n-type semiconductors to fuse with organic p-type semiconductors. In the mixed active layer, phase separation between organic semiconductors and inorganic nanopowder takes place. The photo generated holes are transported to the anode through the organic phase and the electrons are transported to the cathode through the inorganic phase. Since the performance of the solar cell is highly dependent on the efficiency of charge transport in the active layer, it is important to ensure good electrical contact between the inorganic nanopowder. However, since inorganic nanopowder are generally prepared in the presence of long-chain surfactants or ligands (capping agents), electrical contact is generally poor because such surfactants or capping agents tend to act as an electrically insulating layer that prevents oxidation. Efficient charge transfer between nanopowder. To improve on this problem, some researchers have also studied thermally removable ligands (usually short-chain organic molecules). However, the enhancement effect is still not satisfactory. From an electrical contact point of view, the use of inorganic nanopowder with a clean surface (i.e. no surfactants or protective agents) is ideal, as a clean surface would make sintering of the nanopowder relatively easy due to their properties. Higher surface energies, thus improving the electrical contact between them. However, to prepare clean nanopowder, it is necessary to develop a synthesis process without surfactants, which has always been a challenge for researchers.