| Cadmium Telluride Nanopowder | |

| Product No | NRE-5040 |

| CAS No. | 1306-25-8 |

| Formula | CdTe |

| Molecular Weight | 240.01 g/mol |

| APS | <100nm (can be customized) |

| Purity | 99.9% |

| Density | 5.85g/cm3 |

| Color | NA |

| Melting Point | 1,041 °C |

| Boiling Point | 1,050 °C |

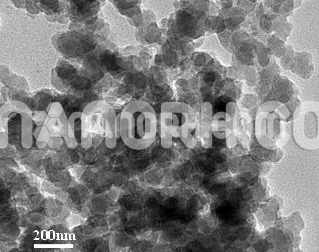

Cadmium Telluride Nanopowder

Cadmium Telluride Nanopowder are one of the few II-VI compounds that can be changed to n-type or p-type by a dopant. It is mainly used as the semiconducting material in cadmium telluride photovoltaic and an infrared optical window. The band gap energy of bulk Cadmium Telluride Nanopowder is 1.44 eV, making them an excellent candidate for solar cell applications, and can be tuned by varying the size of the Nanopowder . The growing interest in solar absorption has led to a demand for the characterization of visible absorbing semiconductor film materials for use in photovoltaic devices. Solar film layers based on Cadmium Telluride Nanopowder have a maximum theoretical efficiency among the individual semiconductors of more than 29% under terrestrial conditions. Many approaches have been proposed for the synthesis of Group II–VI semiconductors, including the well-known solid‐state reaction, novel mechanochemical synthesis, or microwave‐assisted synthesis in organic solvents. Many of these processes require high temperatures, making it difficult to control the size and use of toxic precursors. Cadmium Telluride Nanopowder have also been prepared using different techniques such as Electrodeposition, indoor CSS sublimation, spray pyrolysis, screen printing, atomic layer epitaxy, and RF sputtering. Recently, sonochemical processing has emerged as a useful technique to generate new materials with remarkably smaller dimensions and novel physical properties. Ultrasonic waves are intense enough to cause acoustic cavitation, which can lead to chemical reactions such as oxidation, reduction, dissolution, and decomposition. The formation, growth and implosive collapse of gas bubbles in a liquid leads to a transition temperature of up to ~5000 K and a high pressure of ~1800 atm, followed by rapid cooling to the general temperature. Ultrasonic irradiation causes the formation of particles with a much smaller size and a higher surface area to volume ratio than those reported by other methods, which also have a higher surface activity compared to that of the bulk material.