| Cadmium Zinc Telluride Powder | |

| Product No | NRE-433490 |

| CAS No. | NA |

| Formula | CZT |

| Molecular Weight | 235.31 g/mol |

| Purity | 99.9% |

| Density | NA |

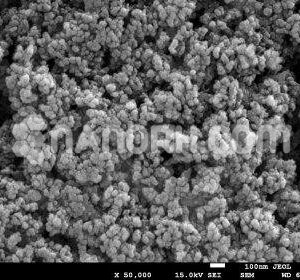

| APS | <40 um (can be customized) |

| Melting Point | 1100-1150 °C |

| Boiling Point | NA |

Cadmium Zinc Telluride Powder

Cadmium zinc telluride (CdZnTe), also known as CZT, is a compound of cadmium, zinc, and tellurium. It is a crystalline, wide-band gap semiconductor material that is used in a variety of applications due to its unique properties. One of its notable characteristics is its ability to detect various types of radiation, making it valuable in the field of radiation detection. Here are some common applications of cadmium zinc telluride powder:

Radiation detection: CdZnTe is primarily used in the manufacturing of radiation detectors, such as X-ray and gamma-ray detectors. Its high atomic number and wide bandgap make it suitable for detecting high-energy gamma rays and X-rays. These detectors are used in medical imaging, security screening, and industrial applications.

Nuclear spectroscopy: CdZnTe detectors are employed in nuclear spectroscopy for the precise identification of radioactive isotopes. They can be used in high-resolution gamma-ray spectroscopy for identifying and quantifying specific radioisotopes in a sample.

Homeland Security: The compound is also utilized in homeland security applications, particularly in the detection of illicit nuclear materials. CdZnTe-based detectors are capable of detecting and identifying radioactive materials in various security settings, including airports, seaports, and border crossings.

Medical imaging: CdZnTe is used in the production of gamma cameras for medical imaging, particularly in single-photon emission computed tomography (SPECT) systems. These cameras are employed for various diagnostic purposes, including the imaging of organs and tissues, as well as in the detection of cancer and cardiovascular diseases.

Industrial applications: CdZnTe detectors find application in industrial settings for non-destructive testing (NDT) and material analysis, especially in industries where there is a need for precise analysis of materials and components. They can be used to identify defects in materials, analyze composition, and perform quality control checks.