Carbon Nanotube Dispersion / CNTs Ester Dispersion

Carbon Nanotube Dispersion -This is a polymer dispersant solution product with a solid content of 45%. The solvent is a mixture of butyl acetate and ethylene glycol butyl ether. Based on our lab experimental results from numerous dispersants screened out, it is particularly suitable for carbon nanotubes to be dispersed in ester solvents such as ethyl acetate, butyl acetate, and the liquid epoxy resin.

| Carbon Nanotube Dispersion | |

| Product No | NRE-36004 |

| CAS No. | NA |

| Purity | > 95 wt% |

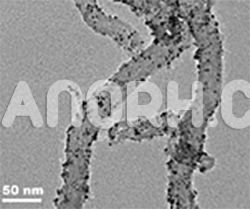

| Average Diameter | 20-30nm |

| Average Length | 5-30 um |

| Special Surface Area(SSA) | > 380 m2/g |

| Tap Density | 0.14g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | > 100 S/cm |

Carbon Nanotube Dispersion Equipment:

Application:

Carbon nanotube dispersion including both and variants, have exceptional properties such as high mechanical strength, thermal conductivity, electrical conductivity, and chemical stability. However, for many applications, CNTs must be properly dispersed in a medium (e.g., water, polymers, solvents) to fully exploit their potential.

To achieve uniform dispersion of CNTs, dispersion equipment is crucial. This equipment is designed to break up CNT aggregates and create a stable, homogeneous dispersion that can be integrated into various applications, such as in composites, electronics, energy storage devices, biomedical applications, and more.

Applications

High-Shear Mixers

Application: High-shear mixers, also known as rotor-stator mixers, use intense mechanical force to shear and break apart CNT agglomerates. These mixers are commonly used in industrial-scale production of CNT dispersions, especially when CNTs need to be incorporated into polymers, paints, coatings, or inks.

Example Application:

Polymer Nanocomposites: In the creation of CNT-reinforced polymer composites, high-shear mixers ensure that the CNTs are uniformly distributed throughout the polymer matrix, enhancing the composite’s mechanical strength and electrical conductivity.

Ultrasonic Dispersers (Ultrasonication)

Application: Ultrasonic dispersers use high-frequency sound waves to generate cavitation in a liquid medium, which creates intense shear forces that break up CNT agglomerates. Ultrasonic dispersing is often used for lab-scale as well as pilot-scale dispersion of CNTs in solvents, water, and biological systems.

Example Application:

Nanocomposites and Coatings: Ultrasonic dispersers are used for preparing CNT-based coatings, inks, and pastes where uniform dispersion is critical for properties like conductivity and adhesion.

Ball Mills

Application: Ball mills are used for wet grinding and dispersing CNTs in liquid mediums. They are effective in breaking up CNT bundles and reducing their size to create fine dispersions. Ball mills can be used on both small and large scales.