| Cerium Sputtering Target | |

| Product No | NRE-43025 |

| CAS No. | 7440-45-1 |

| Formula | Ce |

| Molecular Weight | 140.116 g/mol |

| Purity | >99.9% |

| Density | 6.770 g/cm³ |

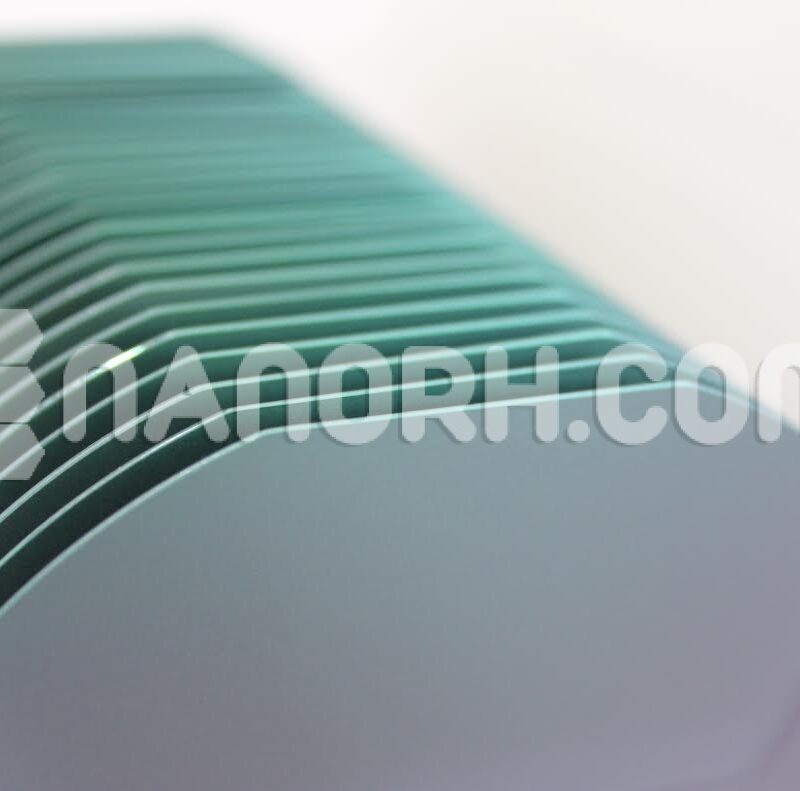

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Electronegativity | NA |

Cerium Sputtering Target

Cerium sputtering targets are used in various advanced technological applications due to cerium’s unique properties. Here’s a detailed look at their role and benefits in different product applications.

Applications of Cerium Sputtering Targets

Optical Coatings:

Anti-Reflective Coatings: Cerium oxide (CeO₂) is widely used in anti-reflective coatings for lenses and optical instruments. These coatings reduce glare and improve the transmission of light through optical elements.

Protective Layers: Cerium-based coatings are also used to enhance the durability and scratch resistance of optical surfaces.

Catalysis:

Automotive Catalysts: Cerium is a key component in catalytic converters used in vehicles. Cerium oxide acts as an oxygen storage component, helping to reduce emissions by facilitating the conversion of pollutants into less harmful substances.

Industrial Catalysts: Cerium sputtering targets can be used to deposit thin films on catalyst supports, improving the efficiency and longevity of industrial catalytic processes.

Semiconductor Industry:

Thin Films for Electronics: Cerium sputtering targets are employed to create thin films in semiconductor devices. These films can be used in various electronic components, such as capacitors and resistors, where cerium’s unique properties contribute to device performance.

Magnetic Materials:

Data Storage: Cerium is used in magnetic thin films and coatings for data storage devices. These films can enhance the performance of hard drives and other storage media by improving magnetic properties.

Fuel Cells:

Electrolytes: Cerium oxide is used in some types of fuel cells, particularly solid oxide fuel cells (SOFCs). Thin films of cerium oxide can serve as electrolyte materials, improving the efficiency and performance of the fuel cells.

Surface Coatings:

Wear-Resistant Coatings: Cerium sputtering targets are used to deposit coatings that enhance the wear resistance of various surfaces. These coatings can be applied to tools, machinery parts, and other components that experience high levels of abrasion.