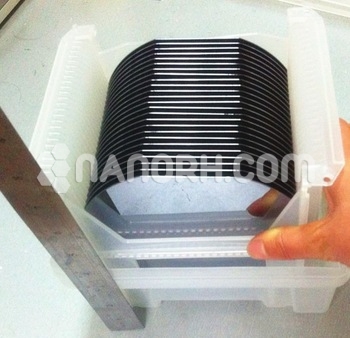

| Chromium Aluminum Alloy Sputtering Targets | |

| Product No | NRE-43359 |

| CAS No. | NA |

| Formula | Cr-Al |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Chromium Aluminum Alloy Sputtering Targets

Chromium aluminum alloy sputtering targets are used in various applications where their unique properties can be leveraged. Here’s a breakdown of different applications and how the characteristics of Al-Cr alloy targets are utilized.

Optical Coatings

Application:

Antireflective Coatings: Used on lenses, glasses, and other optical devices to reduce glare and improve light transmission.

Reflective Coatings: Employed in mirrors and optical filters to enhance reflectivity.

Why Al-Cr?

Optical Performance: The alloy can be engineered to achieve specific optical properties, including desired levels of reflectivity and transmissivity.

Durability: Provides a hard, wear-resistant layer that maintains optical quality over time.

Wear-Resistant Coatings

Application:

Tooling and Machinery: Coatings for cutting tools, dies, and machinery parts to enhance their durability and lifespan.

Why Al-Cr?

Hardness: The chromium content enhances the hardness of the coating, making it suitable for applications requiring high abrasion resistance.

Reduced Friction: The alloy can reduce friction and wear, extending the life of the coated components.

Corrosion-Resistant Coatings

Application:

Aerospace Components: Parts exposed to harsh environments and high temperatures.

Automotive Parts: Engine components and exterior parts requiring resistance to environmental degradation.

Why Al-Cr?

Corrosion Resistance: Chromium provides excellent corrosion resistance, protecting substrates from oxidation and chemical attacks.

Decorative Coatings

Application:

Consumer Electronics: Coatings for devices such as smartphones and watches for aesthetic enhancement.

Jewelry: Used for plating to achieve a specific appearance or color.

Why Al-Cr?

Aesthetic Flexibility: The alloy can be tailored to produce various colors and finishes, making it suitable for decorative purposes.

Durability: Provides a long-lasting finish that resists tarnishing and scratching.

Electromagnetic Shielding

Application:

Electronic Devices: Coatings on components to shield sensitive electronics from electromagnetic interference (EMI).

Why Al-Cr?

Conductivity: The alloy can be designed to have good electrical conductivity, which is crucial for effective EMI shielding.

Uniform Coating: Ensures consistent and reliable performance in shielding applications.

Hard Coatings for Semiconductor Manufacturing

Application:

Semiconductor Devices: Used as hard masks or barrier layers in the fabrication of semiconductor devices.