| Chromium Boride Sputtering Targets | |

| Product No | NRE-43361 |

| CAS No. | NA |

| Formula | Cr5B3 |

| Molecular Weight | 62.807 g/mol |

| Purity | >99.9% |

| Density | NA |

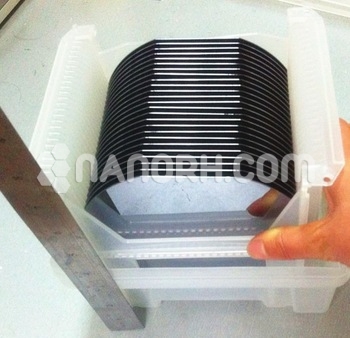

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Chromium Boride Sputtering Targets

Chromium boride (CrB) sputtering targets are utilized in several specialized applications due to their unique properties, including high hardness, wear resistance, and thermal stability. Here’s a detailed look at the specific applications where chromium boride sputtering targets are valuable.

Applications of Chromium Boride Sputtering Targets

Wear-Resistant Coatings

Cutting Tools and Machining Equipment:

Applications: Coatings for drills, mills, lathes, and other cutting tools.

Benefits: Enhances the hardness and wear resistance of tools, extending their lifespan and reducing the frequency of tool replacements.

Industrial Machinery:

Applications: Protective coatings for components subjected to abrasive environments, such as mining or construction equipment.

Benefits: Provides a durable surface that withstands high wear and impact, reducing maintenance costs.

High-Temperature Coatings

Furnace and Engine Components:

Applications: Coatings for parts in high-temperature environments like furnaces, gas turbines, and engine components.

Benefits: Maintains performance and structural integrity at elevated temperatures, improving the efficiency and longevity of high-temperature equipment.

Heat Shields:

Applications: Used in aerospace and industrial applications for heat shields and thermal barriers.

Benefits: Offers excellent thermal stability and protects underlying materials from extreme heat.

Corrosion-Resistant Coatings

Aerospace and Automotive Parts:

Applications: Coatings for parts exposed to harsh environmental conditions, such as aircraft components and automotive parts.

Benefits: Provides resistance to oxidation and chemical corrosion, extending the service life of critical components.

Marine Equipment:

Applications: Coatings for equipment used in marine environments, where exposure to seawater can cause rapid corrosion.

Benefits: Protects against corrosion from seawater and other corrosive elements, reducing maintenance and replacement costs.

Magnetic Materials

Magnetic Sensors and Data Storage Devices:

Applications: Thin films for magnetic sensors, data storage devices, and magnetic recording heads.

Benefits: Depending on the specific formulation, chromium boride can contribute to desired magnetic properties, improving performance and sensitivity.

Optical Coatings

Protective Optical Coatings:

Applications: Coatings for lenses, mirrors, and other optical components.

Benefits: Provides a hard, protective layer that enhances the durability of optical surfaces, protecting them from scratches and other damage.

Semiconductor and Electronics

Thin Films for Electronics:

Applications: Used in electronic components and devices where specific electrical and thermal properties are required.

Benefits: Offers unique electrical and thermal characteristics, beneficial for advanced semiconductor and electronic applications.