| Chromium Carbide Nanopowder | |

| Product No | NRE-5059 |

| CAS No. | 12012-35-0 |

| Formula | Cr3C2 |

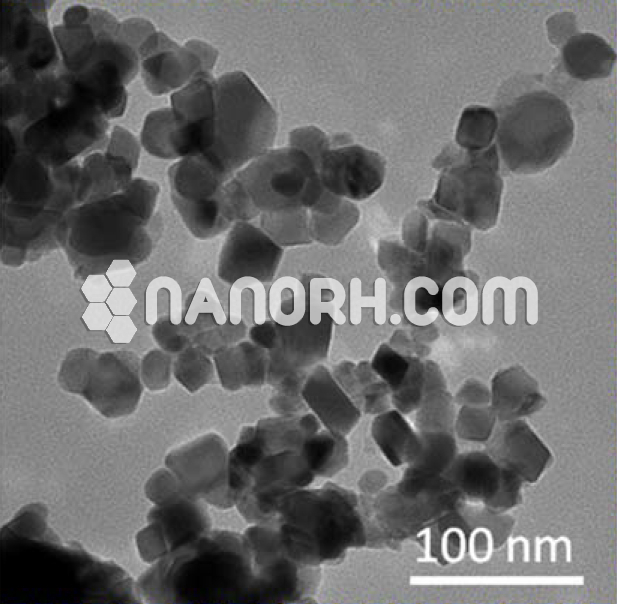

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray-Brown |

| Molecular Weight | 180.0097 g/mol |

| Density | 6.68 g/cm3 |

| Melting Point | 1895°C |

| Boiling Point | 3800°C |

Chromium Carbide Nanopowder

Chromium carbide nanopowder is a ceramic material composed of chromium and carbon, known for its high hardness, excellent wear resistance, high melting point, and resistance to oxidation. When produced in nanopowder form, chromium carbide exhibits even greater mechanical and thermal properties due to the reduced particle size, which enhances surface area and reactivity.

Applications

Wear-resistant Coatings: Chromium carbide nanopowder is frequently used to produce coatings for tools, machinery parts, and components that are subjected to extreme wear and tear. The nanopowder can be sprayed onto surfaces or incorporated into a composite material to improve their hardness and wear resistance.

Cutting Tools: In the manufacturing industry, is used to produce cutting tools and drills, which require materials with high hardness and thermal stability. These tools are particularly useful in metalworking and mining.

Engine Components: Due to its excellent high-temperature performance, chromium carbide is used in engine components that operate in demanding conditions, such as in turbines or exhaust systems, where high temperatures and wear are prevalent.

Surface Protection in Aerospace: The aerospace industry benefits from the use of for protective coatings in aircraft components, where resistance to both heat and corrosion is crucial.

Wear-resistant Polymers and Composites: is incorporated into composite materials to enhance their mechanical properties, including wear resistance and durability. These composites are used in industries like automotive, mining, and construction.