Chromium Carbide Nickel Chromium Alloy Nanoparticles

Chromium Carbide Nickel Chromium Alloy Nanoparticles

| Chromium Carbide Nickel Chromium Alloy Nanoparticles | |

| Product Number | NRE-2005 |

| CAS No. | 12012-35-0/ 7440-02-0 / 7440-47-3 |

| Formula | Cr3C2-NiCr |

| Molecular Weight | 290.69 g/mol |

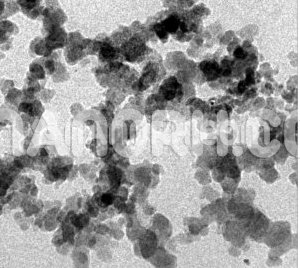

| APS | <100 nm(Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | 2.3 g/cm3 |

| Melting Point | NA |

| Boiling Point | NA |

Chromium Carbide Nickel Chromium Alloy Nanoparticles

Applications

Wear-Resistant Coatings:

Chromium carbide nickel chromium alloy nanoparticles are widely used in wear-resistant coatings for machinery parts and tools. These coatings are applied in industries such as mining, metalworking, and heavy machinery to reduce wear and extend the lifespan of components exposed to friction and abrasion.

Thermal Spray Coatings:

In the thermal spray coating process, these nanoparticles are applied to substrates to provide protection against abrasion, erosion, and high-temperature corrosion. These coatings are commonly used in aerospace components, gas turbines, boilers, and heat exchangers to improve their durability and efficiency under extreme conditions.

Automotive Industry:

The Cr₃C₂-NiCr nanoparticles are used in automotive components that experience high wear, such as engine parts, brake pads, and cylinder heads. The nanoparticles provide increased thermal resistance and abrasion resistance, helping improve the performance and longevity of automotive systems.

Cutting Tools:

Cutting tools such as drills, mills, and saws made from Cr₃C₂-NiCr alloy nanoparticles benefit from enhanced hardness and wear resistance, allowing them to operate more effectively in high-stress manufacturing processes, particularly in the aerospace and precision machining industries.

Oil and Gas Industry:

These nanoparticles are used in the oil and gas industry, particularly for drilling equipment and pipeline coatings, where they provide resistance to wear, high temperatures, and corrosive fluids. This helps improve the reliability and performance of equipment in harsh environmental conditions, such as deep-sea drilling.

Aerospace Applications:

In aerospace, Cr₃C₂-NiCr nanoparticles are used for protective coatings on engine parts, turbines, and other components exposed to extreme heat and mechanical stress. Their thermal stability and oxidation resistance make them ideal for prolonging the service life of these critical aerospace components.

Catalysis:

Due to their high surface area and chemical reactivity, these nanoparticles are explored in catalytic applications, such as in fuel cells, hydrogenation reactions, and environmental pollution control.