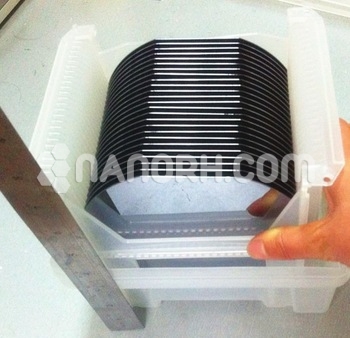

| Chromium Sputtering Target | |

| Product No | NRE-43029 |

| CAS No. | 7440-47-3 |

| Formula | Cr |

| Molecular Weight | 51.996 g/mol |

| Purity | >99.99% |

| Density | 7.19 g/cm³ |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Electronegativity | NA |

Chromium Sputtering Target

Chromium sputtering targets are employed across various applications due to their unique properties, such as hardness, corrosion resistance, and optical qualities. Here’s a breakdown of how chromium sputtering targets are used in different fields.

Industrial Hard Coatings

Cutting Tools and Dies: Chromium coatings are applied to cutting tools, molds, and dies to enhance their hardness and wear resistance. This extends the tool life and maintains sharpness during high-stress machining operations.

Automotive Parts: Components such as pistons, camshafts, and gears benefit from chromium coatings to improve durability and resistance to wear and tear.

Corrosion Protection

Aerospace Components: Chromium coatings protect aerospace parts from harsh environmental conditions, including high temperatures and corrosive substances.

Marine Equipment: In marine environments, chromium coatings are used to prevent corrosion and degradation caused by saltwater and other aggressive elements.

Decorative Coatings

Consumer Goods: Chromium sputtering targets are used to apply shiny, reflective coatings on products like faucets, furniture, and trim pieces. This not only enhances aesthetic appeal but also provides a durable surface.

Automotive Parts: Decorative chromium coatings are applied to automotive parts such as grille inserts, wheels, and mirrors to achieve a high-quality finish and visual appeal.

Optical Coatings

Mirrors and Lenses: Chromium is used to deposit coatings on mirrors and lenses to enhance reflectivity and protect against environmental damage. These coatings are essential in optical instruments, such as telescopes and cameras.

Anti-Reflective Coatings: Chromium coatings are also employed in anti-reflective coatings to reduce glare and improve visibility in various optical devices.

Magnetic Materials

Data Storage: Chromium coatings are utilized in magnetic thin films for data storage applications. They play a role in improving the magnetic properties and stability of storage media.

Sensors: Magnetic sensors that rely on chromium coatings benefit from enhanced sensitivity and performance.

Semiconductor Manufacturing

Interconnects: In semiconductor fabrication, chromium is used for depositing thin films that act as interconnects in integrated circuits, helping to ensure efficient electrical conductivity.

Barrier Layers: Chromium layers are used as diffusion barriers to prevent intermixing of materials during the semiconductor manufacturing process.