| Copper (Cu) Powder | |

| Product No | NRE-8014 |

| CAS No. | 7440-50-8 |

| Formula | Cu |

| Molecular Weight | 63.55 g/mol |

| APS | <40 um (can be customized) |

| Purity | 99.5% |

| Color | Red Brown |

| Density | 8.96 g/cm3 |

| Melting Point | 1084.6°C(lit.) |

| Boiling Point | 2562°C |

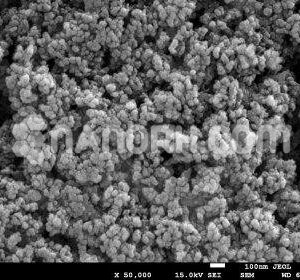

Copper (Cu) Powder

Copper (Cu) powder has a wide range of applications across various industries due to its excellent electrical conductivity, thermal conductivity, corrosion resistance, and malleability. Here are some common applications of copper powder:

Electrical and Electronics:

Electrical conductors: Copper powder is used to make conductive pastes and inks for printed circuit boards (PCBs) and flexible electronics.

Electrical contacts: It is used in the production of electrical contacts, switches, and connectors due to its excellent conductivity.

Electrical motors and transformers: Copper powder is used in the manufacture of windings and coils for motors and transformers.

Powder Metallurgy:

Sintered parts: Copper powder is often used in powder metallurgy processes to create parts and components like bushings, bearings, gears, and filters.

Friction materials: Copper powder is added to friction materials, such as brake pads and clutches, to improve heat dissipation and wear resistance.

Heat Exchangers and Cooling Systems:

Copper powder is used in the manufacturing of heat exchangers, radiators, and cooling fins due to its excellent thermal conductivity.

Welding and Brazing:

Copper powder is used in welding and brazing applications to enhance joint strength and conductivity.

Anti-Fouling Coatings:

In marine applications, copper-based paints and coatings containing copper powder are used to prevent the growth of marine organisms on ship hulls.

Decorative Applications:

Art and crafts: Copper powder is used in various artistic and decorative applications, including sculpture, pottery, and jewelry making.

Chemical Industry:

Catalysts: Copper powder is used as a catalyst in chemical reactions, particularly in processes involving hydrogenation and oxidation.

Additive Manufacturing (3D Printing):

Copper powder is utilized in additive manufacturing processes like selective laser melting (SLM) and powder bed fusion to create complex metal parts.

Thermal Spraying:

Copper powder is used in thermal spraying applications to create wear-resistant coatings on surfaces.

Nanotechnology:

Copper nanoparticles, which can be derived from copper powder, have applications in nanotechnology for their unique properties, such as antimicrobial activity and catalytic behavior.

Lubricants and Oil Additives:

Copper powder is sometimes added to lubricants and oil additives to improve their performance and reduce friction.

Agriculture:

Copper-based fertilizers containing copper powder can be used to correct copper deficiencies in soil and promote plant growth.

Pyrotechnics and Explosives:

Copper powder is used in fireworks and pyrotechnics to produce vibrant blue and green colors when ignited.

Medicine:

In some medical applications, copper powder can be used as a component of wound dressings and as an antimicrobial agent due to its biocidal properties.