| Copper Iron Sulfide Sputtering Targets | |

| Product No | NRE-43397 |

| CAS No. | NA |

| Formula | CuFeS2 |

| Molecular Weight | 183.52 |

| Purity | >99.9% |

| Density | NA |

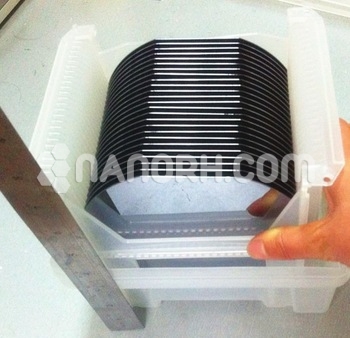

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Copper Iron Sulfide Sputtering Targets

Copper-nickel (Cu-Ni) alloy sputtering targets are used in a range of advanced technological applications due to their unique physical and chemical properties. Here’s a detailed look at their primary applications.

Semiconductor Industry

Interconnects and Contacts: Cu-Ni alloys are employed in the semiconductor industry for creating interconnects and contacts within integrated circuits. The alloy’s combination of copper’s excellent electrical conductivity and nickel’s improved resistance to diffusion and oxidation makes it suitable for high-performance electronic devices.

Optoelectronic Devices

Thin-Film Deposition: Cu-Ni alloys are used to deposit thin films in optoelectronic devices. These films can be used in various applications, including light sensors and light-emitting devices, where the alloy’s properties contribute to device performance.

Thin-Film Transistors (TFTs)

Display Technology: In the production of thin-film transistors, which are key components in LCD and OLED displays, Cu-Ni alloys can be used to form layers that improve the performance and stability of the transistors.

Protective Coatings

Wear and Corrosion Resistance: Cu-Ni alloys are used to produce coatings that provide excellent resistance to wear and corrosion. These coatings are applied to various substrates to enhance their durability and longevity, particularly in harsh environments.

Aerospace and Defense

High-Performance Applications: In aerospace and defense industries, Cu-Ni alloys are utilized for their strength, resistance to corrosion, and thermal stability. They can be used in components that are exposed to extreme conditions, such as high temperatures and corrosive environments.

Chemical and Industrial Applications

Catalysts: Cu-Ni alloys can be used in catalytic applications due to their ability to promote certain chemical reactions. The alloy’s properties make it suitable for use in industrial catalytic processes.

Industrial Equipment: The alloy’s resistance to corrosion and wear makes it suitable for use in various industrial equipment and components that require long-term durability.

Research and Development

Material Science: Cu-Ni alloy sputtering targets are valuable in research settings where new materials and technologies are explored. Researchers may investigate different alloy compositions and sputtering techniques to optimize film properties for specific applications.