Copper Nanoparticles / Nanopowder (Cu, 99.9%, 500 nm, metal basis)

The shallow conductive covering handling of metal and non-ferrous metal; Medicine attach material; Capacitor materials; Raw material for mass nanomaterial: Adopt the dormant gas to influence mass to copper nano composite material with powder metallurgy; Cu Nanoparticles widelly utilized as Catalysts; Efficacious impetus: Copper and copper amalgam nanometer, include high adequacy and selectivity, can be utilized as impetus in a few responses, e.g. carbon dioxide compound hydrogen to create methanol; Cu Nanoparticles utilized as Conductive coatings; Conductive inks

| Copper Nanoparticles | |

| Product No | NRE-1010 |

| CAS No. | 7440-50-8 |

| Formula | Cu |

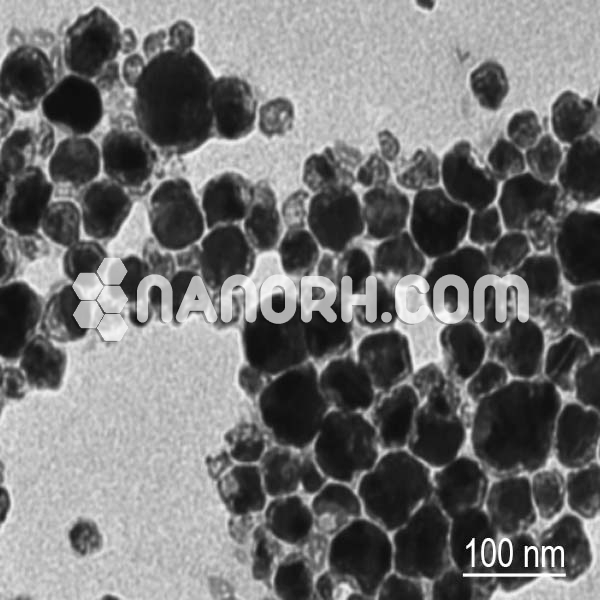

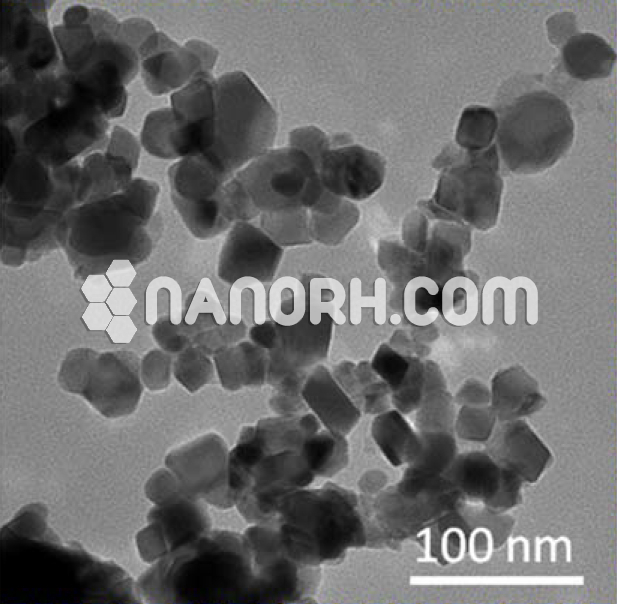

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | reddish-brown |

| Molecular Weight | 63.546 g/mol |

| Density | 8.96g/cm³ |

| Melting Point | 1084.6 °C |

| Boiling Point | 2562 °C |

Copper (Cu) Nanoparticles Applications:

Copper nanoparticles have unique properties compared to bulk copper and can be used in a variety of applications. Here are some common applications of copper nanoparticles:

Conductive inks and coatings: Copper Nanopowder is used to create conductive inks and coatings for printed electronics, flexible electronics, and solar cells. They provide excellent electrical conductivity and are highly efficient at converting sunlight into electricity.

Antimicrobial applications: Copper Nanopowder has strong antimicrobial properties and is used in applications such as wound dressings, medical devices, and water treatment to prevent the growth of bacteria and other microorganisms.

Catalysis: Copper Nanopowder is used as a catalyst in a variety of chemical reactions, including oxidation, reduction, and hydrogenation.

Lubricants and additives: Copper Nanopowder is used as lubricants and additives in metalworking and manufacturing processes. They improve the wear resistance and friction properties of the materials.

Magnetic storage media: Copper Nanopowder are used in magnetic storage media, such as hard disk drives, to improve their magnetic properties and increase their storage capacity.

Energy storage: Copper Nanopowder are used in energy storage applications, such as lithium-ion batteries, to improve their performance and increase their energy density.

Biomedical imaging: Copper Nanopowder is used in biomedical imaging applications, such as magnetic resonance imaging (MRI) and computed tomography (CT) scans, to enhance the contrast and improve the resolution of the images.