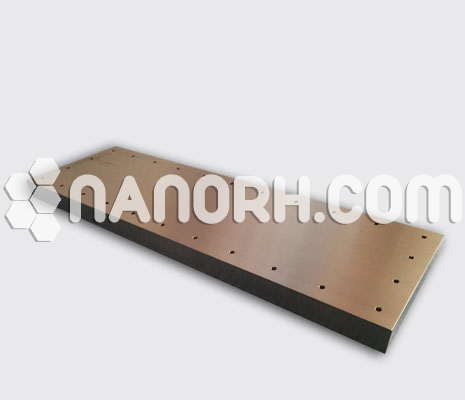

| CuNiTi Sputtering Target | |

| Product No | NRE-43045 |

| CAS No. | NA |

| Formula | CuNiTi |

| Molecular Weight | NA |

| Purity | 99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

CuNiTi Sputtering Target

CuNiTi (Copper-Nickel-Titanium) sputtering targets are used to deposit thin films with unique properties into various applications. The combination of copper (Cu), nickel (Ni), and titanium (Ti) in these sputtering targets imparts several desirable characteristics to the films. Here’s a detailed look at the applications and properties of CuNiTi sputtering targets.

Magnetic Materials:

Use: CuNiTi sputtering targets are often used to create thin films with specific magnetic properties. The combination of copper, nickel, and titanium can result in materials with tailored magnetic behavior, which can be crucial for applications in magnetic sensors, memory devices, and other spintronic devices.

Benefit: The alloy’s composition allows for fine-tuning of magnetic properties, including coercivity and magnetic permeability.

Shape Memory Alloys:

Use: CuNiTi can be used to deposit thin films of shape memory alloys, which exhibit significant changes in shape in response to temperature changes. These materials are used in applications where mechanical actuation is needed, such as in microelectromechanical systems (MEMS) and actuators.

Benefit: The shape memory effect enables precise control and movement in response to thermal stimuli, making these materials valuable in various mechanical and aerospace applications.

Thin Film Coatings:

Use: CuNiTi sputtering targets can be employed to deposit thin films with special mechanical and chemical properties. These films can be used for protective coatings, decorative finishes, or functional layers in various devices.

Benefit: The alloy’s properties can enhance wear resistance, corrosion resistance, or provide specific electrical or thermal conductivity.

Electronics and Sensors:

Use: In the electronics industry, CuNiTi thin films can be used in sensors, connectors, and other electronic components. The alloy’s combination of metals can offer improved performance in terms of electrical conductivity and thermal stability.

Benefit: Enhanced reliability and performance in electronic components due to the tailored properties of the alloy.

Research and Development:

Use: Researchers utilize CuNiTi sputtering targets to investigate the properties and applications of this alloy. Studies may focus on understanding the fundamental properties of the alloy or developing new technologies and applications.

Benefit: Exploration of new materials and technologies, potentially leading to advancements in various fields.