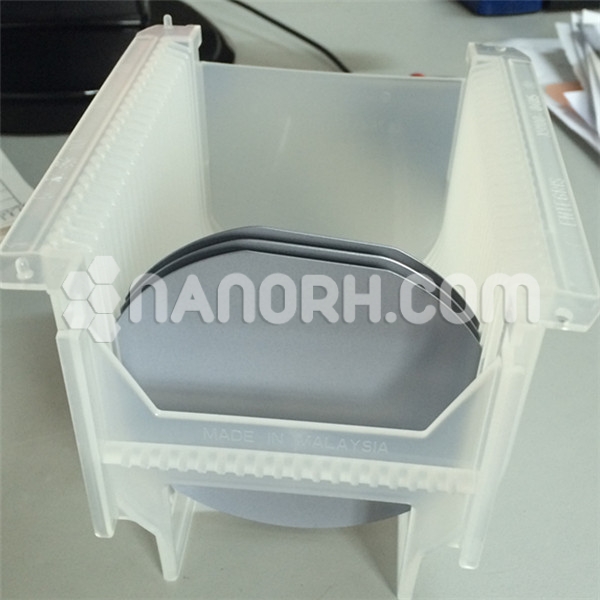

| Fe2TiSi Sputtering Targets | |

| Product No | NRE-43411 |

| CAS No. | NA |

| Formula | Fe2TiSi |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Fe2TiSi Sputtering Targets

The Fe₂TiSi sputtering target is used in thin-film deposition processes, specifically for applications that require the deposition of iron-titanium-silicon (Fe-Ti-Si) alloy films. These films can have unique properties beneficial for various technological applications. Here are some common applications and reasons for using Fe₂TiSi sputtering targets.

Magnetic Materials: Fe-Ti-Si alloys can be used to create thin films with specific magnetic properties. These films are often employed in magnetic sensors, data storage devices, and other applications where magnetic performance is crucial.

Hard Coatings: The Fe-Ti-Si alloy can form hard and wear-resistant coatings, making it suitable for protective layers on tools, machinery, and other surfaces that experience high wear.

Semiconductors: In semiconductor manufacturing, Fe-Ti-Si films can be used in the fabrication of electronic components, where specific electrical and thermal properties are needed.

Catalysts: Some Fe-Ti-Si alloy films might act as catalysts in chemical reactions, enhancing the efficiency of industrial processes.

Optical Coatings: The alloy can also be used in optical coatings for applications that require precise control over light reflection and transmission.

Sputtering is a physical vapor deposition (PVD) technique that involves ejecting material from a target (the Fe₂TiSi sputtering target) and depositing it onto a substrate to form a thin film. The choice of Fe₂TiSi as a target material depends on the desired properties of the deposited film and the specific requirements of the application.