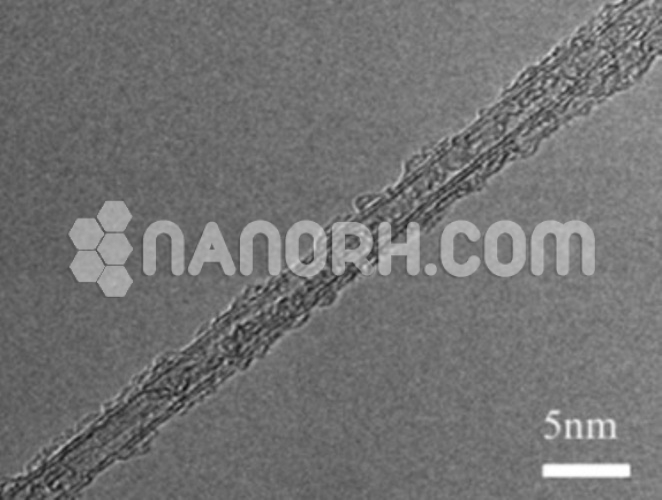

Graphitized MWNTs (>99.9%, OD: 10-20nm)

Graphitized high purity multi-walled carbon nanotubes (MWNTs) were produced by a low temperature CVD method and subsequently annealed about twenty (20) hours under condition of inert gas at temperatures between 1600 and 3000°C. These products were characterized for chemical purity, interlayer spacing, and defect healing. The graphitization procedure was found to remove residual metal catalyst in the nanotubes and reduce the wall defects as reflected in a reduced interlayer spacing between the graphene shells. The graphitized MWNTs have the highest graphite crystallization, the high electrical conductivity and the excellent inoxidizability. The electrical conductivity of the graphitized MWNTs is very close to that of graphite powder. And its ignition temperature can reach 800°C.

| Graphitized MWNTs | |

| Product No | NRE-40004 |

| CAS No. | NA |

| Purity | Carbon nanotubes > 95wt% |

| Average Diameter | 10-20 nm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | >100m2/g(BET) |

| Tap Density | NA |

| True Density | 2.1g/cm3 |

| Electric Conductivity | > 100 S/cm |

Graphitized MWNTs

Introduction

Graphitized MWNTs are cylindrical nanostructures made from multiple concentric layers of graphene sheets rolled into tubes. These tubes can range in diameter from 1 to 100 nano meters, with lengths that can extend up to several micrometers. Graphitization refers to the process of enhancing the alignment of the graphene sheets within the nanotube structure, improving the overall properties of the material. This process involves heating the nanotubes to high temperatures, typically above 2000°C, in the presence of a gas such as argon or hydrogen, which causes the carbon atoms to rearrange and form a more crystalline, graphite-like structure.

Composite Materials

Reinforcement in Polymers: Graphitized MWNTs are widely used to reinforce polymers, improving their mechanical properties, such as tensile strength, stiffness, and impact resistance. The graphitized structure leads to better load transfer between the nanotubes and the matrix, making them ideal for high-performance composites used in aerospace, automotive, and electronics.

Thermoplastic and Thermosetting Polymers: Graphitized MWNTs are incorporated into thermoplastics and thermosets to improve not only their mechanical properties but also their thermal and electrical conductivity. These composites are used in applications requiring both structural strength and heat dissipation, such as in electronic enclosures, cooling systems, and lightweight materials.

Nanocomposites in Structural Applications: For high-performance materials, such as in construction or sporting goods, graphitized MWNTs provide exceptional mechanical reinforcement while also enhancing the thermal stability and conductivity of the composite.

Energy Storage and Conversion

Supercapacitors: Graphitized MWNTs are used in supercapacitor electrodes due to their excellent electrical conductivity and high surface area. The high aspect ratio and conductivity of the tubes allow for efficient charge storage and fast charge/discharge rates, improving the performance and energy density of supercapacitors.

Lithium-Ion Batteries: In the development of high-capacity anodes for lithium-ion batteries, graphitized MWNTs enhance the electrical conductivity and capacity retention during cycles. The alignment of the graphene sheets in graphitized MWNTs contributes to better charge/discharge rates and extended battery life.

Fuel Cells: Graphitized MWNTs are also explored for use in the electrodes of fuel cells, particularly in proton-exchange membrane (PEM) fuel cells, where their high conductivity and stability under harsh conditions improve electrochemical performance, such as in hydrogen oxidation or oxygen reduction reactions.

Electronics and Nanoelectronics

Field-Effect Transistors (FETs): Due to their superior electrical conductivity, graphitized MWNTs are used in the fabrication of carbon nanotube field-effect transistors (CNT-FETs), which are seen as a potential alternative to silicon-based FETs in high-performance electronics, especially in flexible or transparent electronics.

Conductive Films and Coatings: Graphitized MWNTs are integrated into conductive films or coatings for applications like touchscreens, flexible circuits, and antennas. Their high electrical conductivity, coupled with their lightweight nature, makes them ideal for use in flexible electronics and next-generation communication devices.

Electromagnetic Shielding: MWNTs are used in the development of materials with electromagnetic interference (EMI) shielding properties. Their graphitized structure allows for effective reflection and absorption of electromagnetic waves, making them useful in protecting sensitive electronics from radiation.