Iron Copper Gold Platinum Palladium Silver Core Shell Nanoparticles (Fe, Cu/Au, Pd, Pt, Cu, 99.99%, APS: 80-100nm, Metal Core/Metal Shell)

| Iron Copper Gold Platinum Palladium Silver Core-Shell Nanoparticles | |

| Product No | NRE-16048 |

| CAS No. | 7439-89-6/7440-50-8 |

| Formula | Fe, Cu |

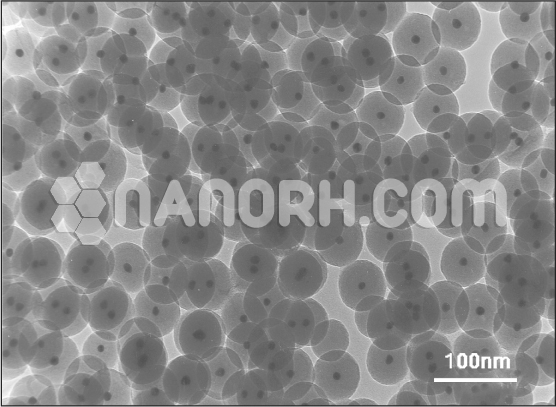

| APS | <100nm (can be customized) |

| Shape | Spherical |

| Purity | 99.9% |

| Core | Iron, Copper (Fe, Cu) |

| Shell | Gold, Platinum, Palladium, Silver |

| Appearance | Powder |

| Boiling Point | NA |

Iron Copper Gold Platinum Palladium Silver Core-Shell Nanoparticles

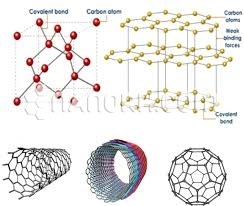

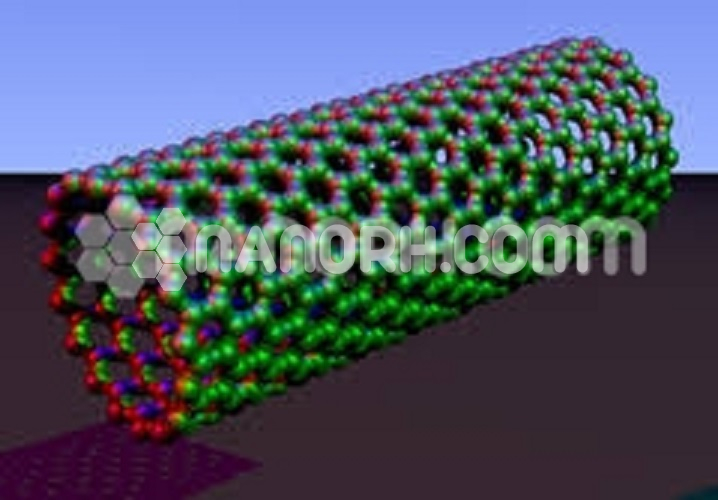

Iron Copper Gold Platinum Palladium Silver Core-shell Nanoparticles are a remarkable class of multimetallic nanomaterials that combine the unique properties of multiple metals in a single nanoparticle structure. These core-shell nanoparticles consist of a core made up of one metal, typically iron (Fe) or a combination of metals, which is then coated with several layers of different metals, such as copper (Cu), gold (Au), platinum (Pt), palladium (Pd), and silver (Ag). Each of these metals contributes to distinct physical, chemical, and electronic properties that are critical for a wide range of applications, including catalysis, biosensing, energy storage, environmental remediation, and biomedical technologies.

In core-shell nanoparticles, the core typically provides the base material with a certain property, such as magnetic behavior (e.g., iron), while the shell enhances the core’s performance by providing additional functionality, like electronic tuning or chemical stability (as in gold or platinum). The sequential addition of metals to form the core-shell structure allows for a synergistic effect, where the properties of the individual metals are optimized, leading to improved overall performance in specific applications.

The combination of multiple metals in a core-shell nanoparticle not only maximizes the advantages of each individual metal but also minimizes their drawbacks. For example, while iron offers magnetic properties and catalytic behavior, it is prone to oxidation, which is mitigated by the presence of gold or platinum shells. Gold provides excellent stability and biocompatibility, while platinum and palladium are highly active for catalytic reactions, especially in hydrogenation and fuel cell technologies. Copper and silver, on the other hand, offer electronic conductivity and plasmonic properties that enhance the overall functionality of the nanoparticles.

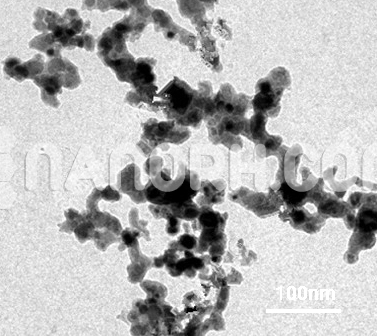

Design and Synthesis

The design and synthesis of Fe-Cu-Au-Pt-Pd-Ag core-shell nanoparticles require sophisticated techniques to control the morphology, size, composition, and core-shell architecture. Various methods are employed to synthesize these nanoparticles, such as:

Seed-Mediated Growth: In this method, a small nanoparticle seed (typically of iron or copper) is used as a template, onto which additional metal layers (gold, platinum, palladium, etc.) are deposited in a controlled fashion. This approach allows for precise control over the thickness of each metal layer and ensures the formation of a true core-shell structure.

Chemical Vapor Deposition (CVD): This method is often used for the deposition of gold, platinum, or palladium layers onto a metal core. CVD allows for high-quality, uniform coating of the core material with thin layers of various metals.