| Lanthanum Copper Manganate Sputtering Targets | |

| Product No | NRE-43230 |

| CAS No. | NA |

| Formula | La2CuMnO6 |

| Molecular Weight | NA |

| Purity | >99.9% |

| Density | NA |

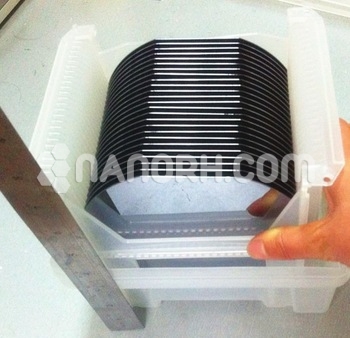

| Thickness | 3 mm ± 0.5mm |

| Diameter | 50 mm ± 1mm |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Lanthanum Copper Manganate Sputtering Targets

Introduction

Lanthanum Copper Manganate (La₂CuMnO₆) is a perovskite oxide known for its intriguing electrical, magnetic, and structural properties. This compound, which incorporates both copper and manganese, is particularly noted for its potential applications in superconductivity and multiferroic materials. The unique combination of these elements allows for tunable properties, making it a subject of interest in various advanced technology sectors.

Applications

High-Temperature Superconductors: La₂CuMnO₆ is studied for its superconducting properties, especially when doped or combined with other materials. It can be used in the fabrication of superconducting films for electronics and power applications.

Multiferroic Materials: This compound exhibits both ferroelectric and magnetic properties, making it valuable in the development of multiferroic devices that can be used in memory storage and spintronic applications.

Electrochemical Devices: La₂CuMnO₆ is also explored for use in solid oxide fuel cells (SOFCs) and other electrochemical systems, where its ionic conductivity can enhance performance.

Magnetic Sensors: The magnetic properties of this material make it suitable for use in various magnetic sensor applications, which can be critical in automotive and industrial settings.

Catalysis: Lanthanum copper manganate has potential as a catalyst in various chemical reactions, particularly those involving oxidation processes.

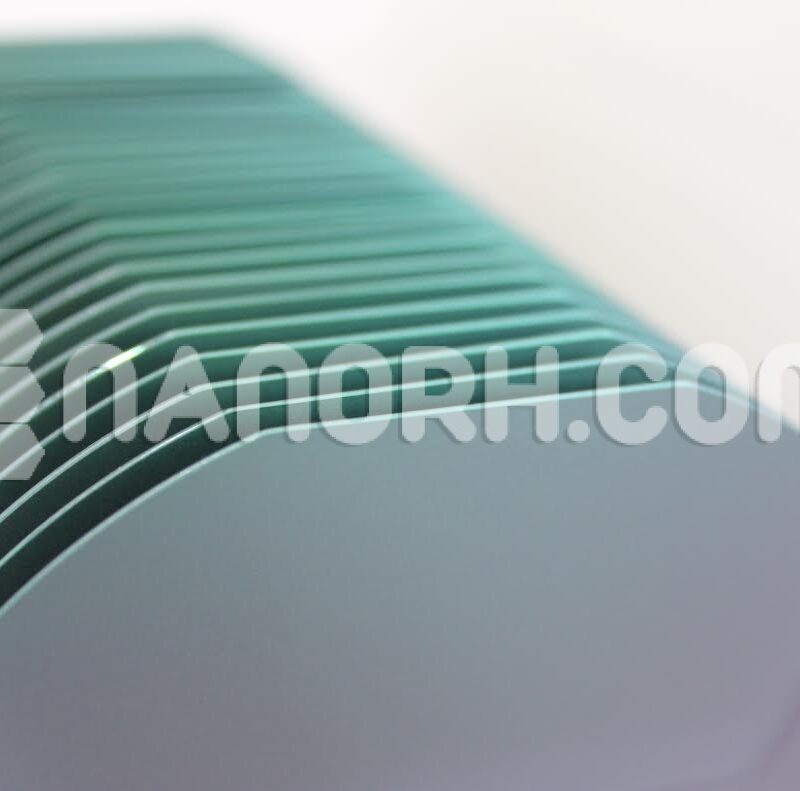

Sputtering Process

Sputtering is a critical technique for depositing thin films of La₂CuMnO₆ onto substrates. In this process, high-energy ions bombard the target, ejecting atoms that are then deposited onto a substrate. This method allows for precise control over the film’s thickness and composition, which is essential for optimizing the performance of devices in which La₂CuMnO₆ is utilized.