| Neodymium Boride Sputtering Targets | |

| Product No | NRE-43509 |

| CAS No. | 12008-23-0 |

| Formula | NdB6 |

| Molecular Weight | 209.108 |

| Purity | >99.9% |

| Density | 4.93 g/cm3 |

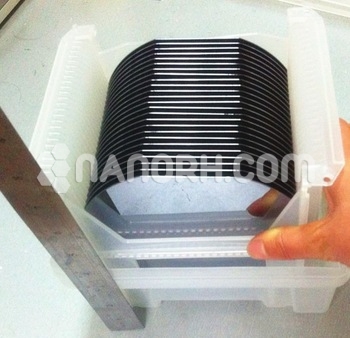

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Neodymium Boride Sputtering Targets

Introduction

Neodymium Boride (NdB6) is a binary compound composed of neodymium and boron, known for its unique properties that make it valuable in various high-performance applications. NdB6 is characterized by its high hardness, thermal stability, and excellent electrical conductivity, positioning it as a significant material in advanced technology sectors.

Properties of Neodymium Boride

High Hardness: NdB6 exhibits excellent hardness, making it suitable for applications requiring wear resistance and durability.

Electrical Conductivity: This material has good electrical conductivity, which is beneficial in electronic and magnetic applications.

Thermal Stability: NdB6 can withstand high temperatures without significant degradation, making it suitable for high-temperature applications.

Magnetic Properties: The compound may also exhibit interesting magnetic properties, particularly when combined with other materials.

Applications

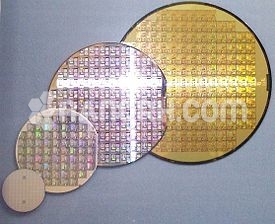

Hard Coatings: NdB6 is used to create hard coatings for tools, machinery, and components to enhance wear resistance and extend their operational life.

Magnetic Materials: Due to its magnetic properties, NdB6 can be utilized in the production of advanced magnetic materials for various applications, including motors and generators.

Electronic Devices: Sputtered NdB6 films can be incorporated into electronic devices, contributing to improved performance in sensors and other components.

Research and Development: NdB6 sputtering targets are often used in laboratories to explore new materials and thin-film technologies, particularly in studies related to superconductivity and magnetism.

Thermal Barrier Coatings: The thermal stability of NdB6 makes it a candidate for thermal barrier coatings in high-temperature environments, such as gas turbines.