| Precipitated Calcium Carbonate Nanoparticles | |

| Product No | NRE-4014 |

| CAS No. | 471-34-1 |

| Formula | CaCO3 |

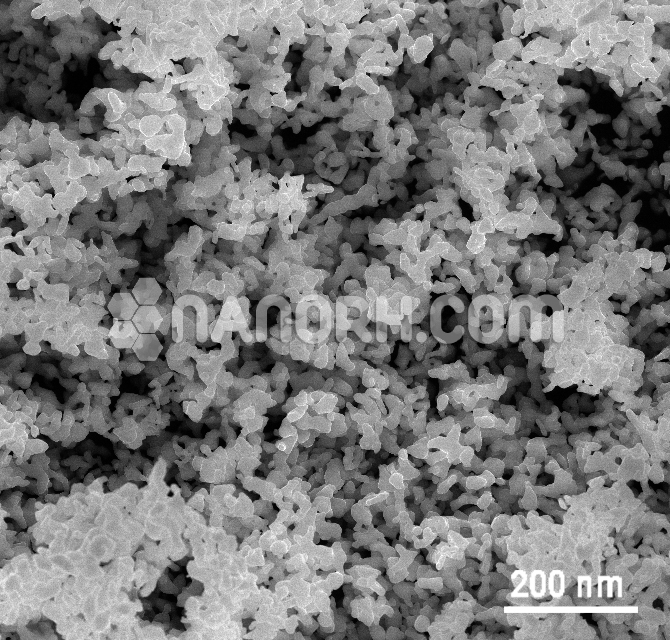

| APS | <100nm (Can be Customized) |

| Purity | 98% |

| Color | white |

| Molecular Weight | 100.0869 g/mol |

| Density | 2.71 g/cm³ |

| Melting Point | 1339 °C |

| Boiling Point | NA |

Precipitated Calcium Carbonate CaCO3 Nanoparticles / CaCO3 Nanopowder

Precipitated Calcium Carbonate nanoparticles / nanopowder is a high-purity, fine form of calcium carbonate (CaCO₃), produced by a precipitation process, which typically involves the reaction of a calcium salt (e.g., calcium hydroxide or calcium chloride) with carbon dioxide (CO₂) in water. When produced in the nanoparticle size range, PCC nanoparticles exhibit unique properties due to their small particle size, high surface area, and versatility in various industrial and scientific applications.

Applications

Paper Industry:

Filler Material: PCC nanoparticles are widely used in the paper industry as fillers to enhance whiteness, opacity, and brightness of paper. They improve the surface smoothness of paper, resulting in a better printing quality.

Coating Pigment: Due to their fine particle size and high brightness, PCC nanoparticles are used in coating pigments for high-quality printed paper, such as magazines, labels, and packaging materials.

Paints and Coatings:

White Pigment: PCC nanoparticles are widely employed in paint and coating formulations as extenders and whiteness enhancers. Their small particle size and high reflectivity help to improve brightness and opacity of paints, offering a cost-effective alternative to other pigments.

Matte Finish and Durability: The use of PCC in coatings can also provide a matte finish, contributing to aesthetic qualities while increasing the durability and scratch resistance of the painted surface.

Plastics and Polymers:

Fillers for Strength and Cost Reduction: PCC nanoparticles are used as fillers in plastics and polymer composites to improve mechanical properties, including strength, rigidity, and thermal stability, while reducing the overall cost of the material. They are commonly used in polypropylene, polystyrene, and PVC.

Improved Processability: The inclusion of PCC nanoparticles can improve the flowability and processability of plastic formulations, especially in injection molding and extrusion processes.

Pharmaceuticals:

Excipient in Tablets and Capsules: PCC nanoparticles are used as excipients in pharmaceutical formulations. They help in the formation of tablets and capsules by improving the flowability of powders, aiding in compression and binding. The fine particle size of PCC ensures better bioavailability of active ingredients.

Drug Delivery Systems: The biocompatibility and surface chemistry of PCC nanoparticles allow them to be used in drug delivery systems, where they can facilitate the controlled release of drugs. Their low toxicity and high surface area make them suitable for use in oral, topical, and inhalable formulations.

Cosmetics and Personal Care:

Cosmetic Fillers and Pigments: PCC nanoparticles are used in cosmetics such as foundations, powders, lotions, and sunblock. Their white color, opacity, and smooth texture enhance the appearance and feel of cosmetic products.

Anti-aging Formulations: Due to their nano-sized particles, PCC nanoparticles are sometimes used in anti-aging creams and wrinkle treatments. Their fine size helps improve the penetration of the active ingredients into the skin.