|

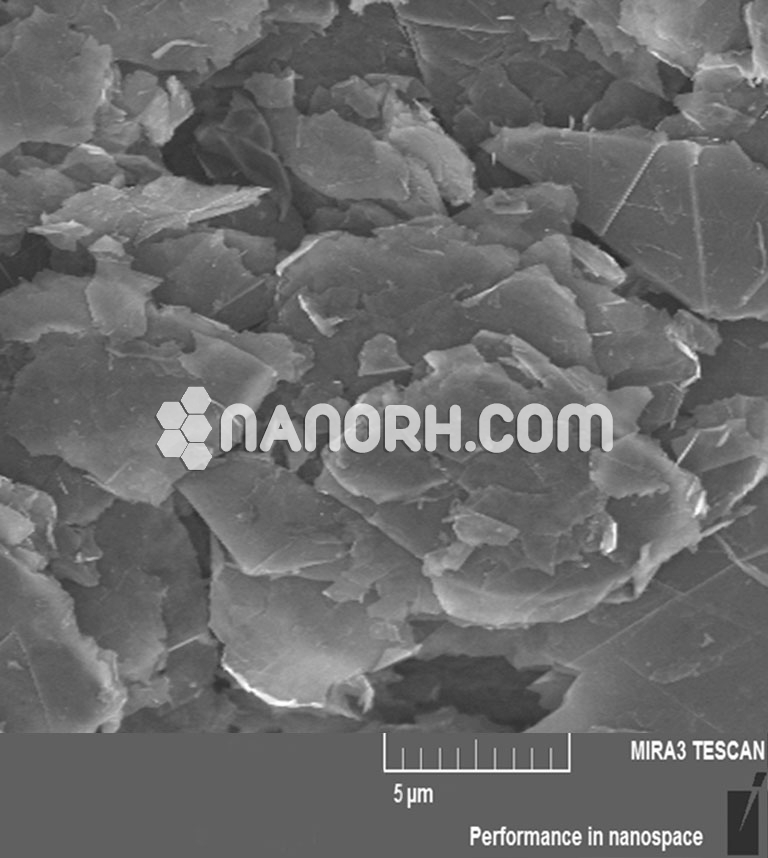

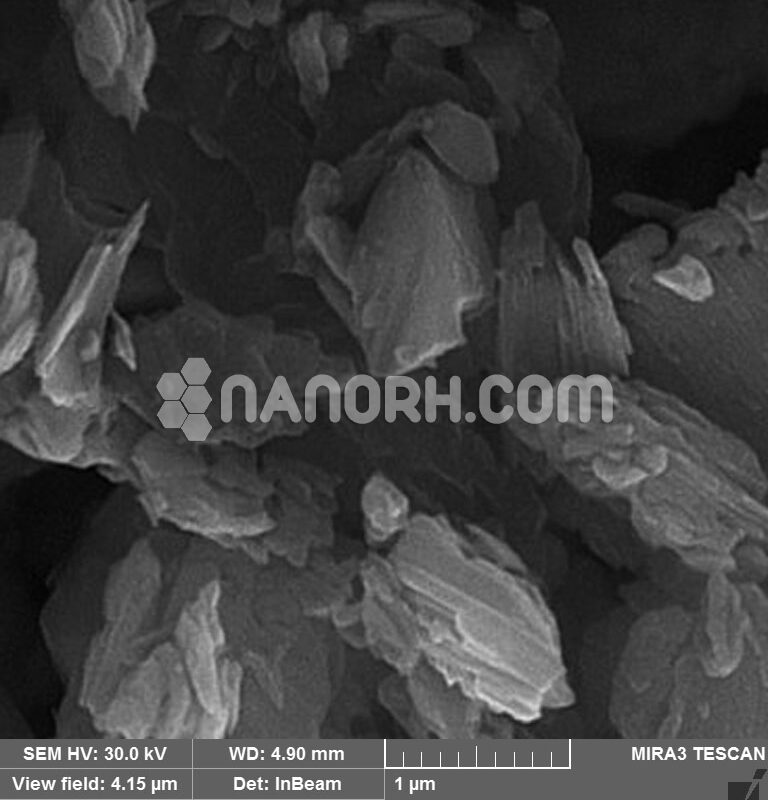

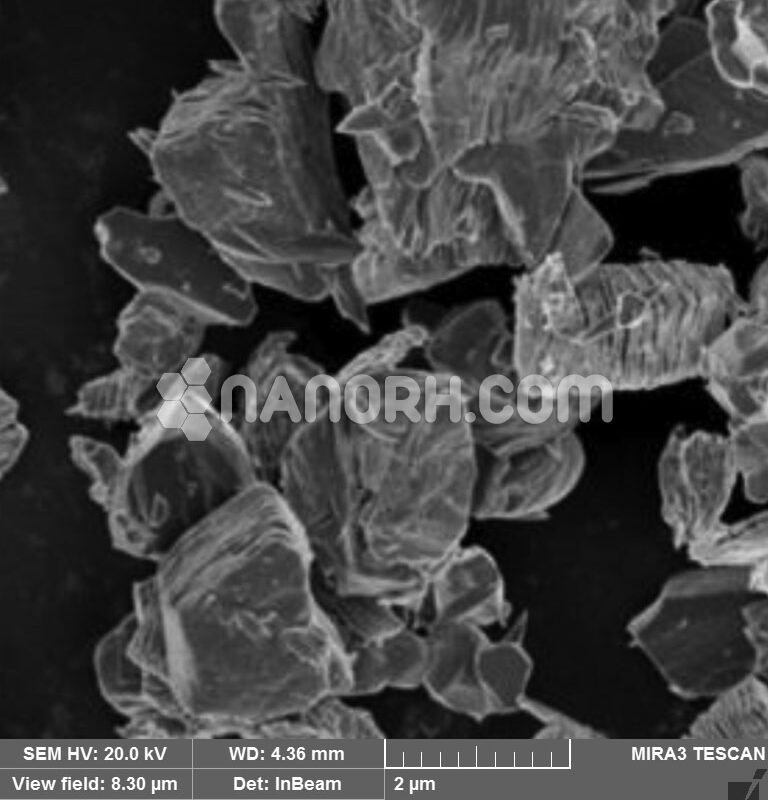

Scandium Aluminum Carbide MAX Phase Powder |

|

| Product No. | NRE-58017 |

| CAS No. | 12316-56-2 |

| Formula | ScAl3C3 |

| Molecular Weight | 161.93 g/mol |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

Scandium Aluminum Carbide MAX Phase Powder

Scandium aluminum carbide (ScAl3C3) is a member of the MAX phase family, which is known for combining the properties of metals and ceramics. ScAl3C3 is characterized by its high thermal and electrical conductivity, mechanical strength, and thermal stability. Here’s how ScAl3C3 MAX phase powder is applied in various industries:

High-Temperature Structural Materials

Application: High-temperature coatings and structural components.

Role: ScAl3C3high melting point and excellent thermal stability make it suitable for applications involving extreme temperatures. It is used to create coatings and structural components that can withstand high-temperature environments, such as in aerospace and industrial applications where materials are exposed to significant thermal stress.

Wear-Resistant Coatings

Application: Protective coatings for cutting tools, industrial machinery, and components.

Role: Due to its hardness and resistance to wear and abrasion, ScAl3C3 is used in protective coatings for tools and machinery. These coatings enhance the durability and performance of cutting tools and other components that experience high wear and tear.

Thermal Barrier Coatings

Application: Thermal barrier coatings for turbines, engines, and other high-temperature systems.

Role: ScAl3C3thermal insulating properties make it suitable for use as a thermal barrier coating. These coatings help protect underlying materials from extreme heat, improving performance and longevity in applications such as gas turbines and jet engines.

Electrical Contacts and Conductive Components

Application: Electrical contacts, conductive coatings, and electrodes.

Role: ScAl3C3 provides good electrical conductivity, which is beneficial for electrical contacts and conductive components. It is used in situations where maintaining reliable electrical performance while withstanding high temperatures and corrosive environments is critical.

Catalysis

Application: Catalysts and catalyst supports for chemical reactions.

Role: ScAl3C3 can be employed as a catalyst or a catalyst support material in various catalytic processes. Its high thermal stability and unique properties can enhance catalytic activity and longevity, especially in high-temperature reactions.

Composite Materials

Application: Reinforced composites and advanced material systems.

Role: Incorporating ScAl3C3 into composite materials can improve their mechanical properties, thermal stability, and resistance to wear and corrosion. This application leverages the material’s unique properties to create advanced composites for specialized uses.

Nuclear Applications

Application: Nuclear reactor components.

Role: ScAl3C3high thermal conductivity and stability make it a candidate for use in nuclear reactor components. It can be used in environments where high thermal conductivity and resistance to radiation damage are required.