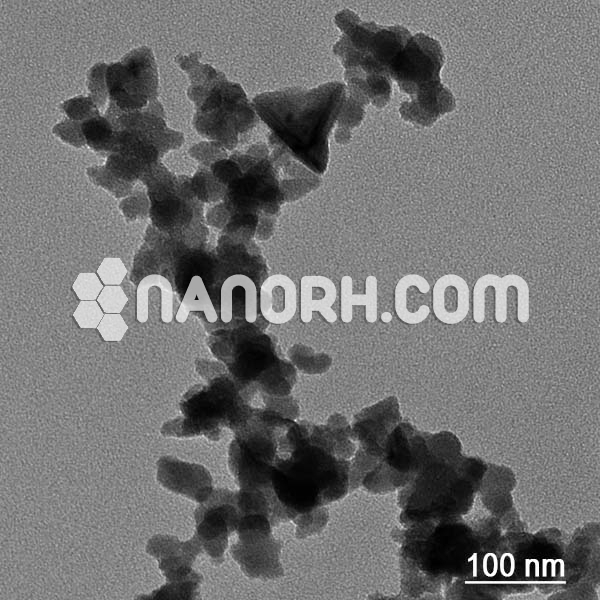

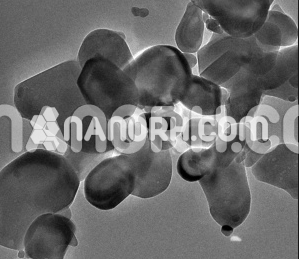

Silicon Carbide (SiC) Nanopowder / Nanoparticles (SiC, beta, 99+%, <80 nm, cubic)

High-review recalcitrant material; Special utilize material for cleaning grating; Ceramic course; Ceramic motor parts; Grinding wheels; Textile earthenware production; High-recurrence pottery; Hard circle and a help for multichip modules; High-temperature and high-control semiconductors; High-temperature artistic orientation; High-temperature liquid transport parts; High hardness pounding materials; High-temperature fixing valves; High-temperature splash spouts;

| Silicon Carbide Nanopowder | |

| Product No | NRE-5197 |

| CAS No. | 409-21-2 |

| Formula | SiC |

| APS | <80nm (Can be Customized) |

| Purity | 99+% |

| Color | bluish-black |

| Molecular Weight | 40.0962 g/mol |

| Density | 3.16 g/cm³ |

| Melting Point | 2830°C |

| Boiling Point | NA |

Silicon Carbide (SiC) Nanopowder General Features:

1. The item has high immaculateness, limit extend molecule estimate circulation, and bigger particular surface territory; 2.This item has concoction steadiness, high warm conductivity, littler warm development coefficient, and better-scraped spot protection; 3. Its microhardness is 2840 ~ 3320kg/mm2 and hardness is amongst corundum and jewel; Its mechanical quality is higher than the corundum; 4. nano-SiC has phenomenal warm conductivity. It is a semiconductor and impervious to oxidation at high temperatures.

Silicon Carbide (SiC) Nanopowder Applications:

High-review recalcitrant material; Special utilize the material for cleaning grating; Ceramic course; Ceramic motor parts; Grinding wheels; Textile earthenware production; High-recurrence pottery; Hard circle and help for multichip modules; High-temperature and high-control semiconductors; High-temperature artistic orientation; High-temperature liquid transport parts; High hardness pounding materials; High-temperature fixing valves; High-temperature splash spouts; Integrated circuit substrate; Catalyst bolster; Mirror or coatings for an extraordinary bright condition; Nanocomposites (e.g., Si3N4/SiC, SiC/polymer); Resistance warming components; Strengthening materials for Al, Al2O3, Mg, and Ni……

Silicon Carbide (SiC) Nanopowder Storage Conditions:

A clammy gathering will influence its scattering execution and utilizing impacts, subsequently, this item ought to be fixed in a vacuum and put away in the cool and dry room and it ought not to be the presentation to air. Also, the item ought to be maintained a strategic distance from under anxiety.