Silicon Graphene Carbon Nanotubes Mixed 6wt% in Water Dispersion

The product is composed of highly electric conductive graphene and highly conductive carbon black nanopowder. The carbon black nanoparticles can not only prevent dispersed graphene from reagglomerating, but also exhibit synergetic effect with graphene. By mixing the two conductive products, it can effectively improve the electrical conductivity, thermal conductivity and mechanical properties; effectively enhance tensile strength, hardness and elastic modulus characteristics, and provide higher electrode conductivity and stronger electrode mechanical strength and adhesive attraction

| Silicon Graphene Carbon Nanotubes Mixed 6wt% in Water Dispersion | |

| Product No | NRE-39028 |

| CAS No. | NA |

| Purity | > 97% |

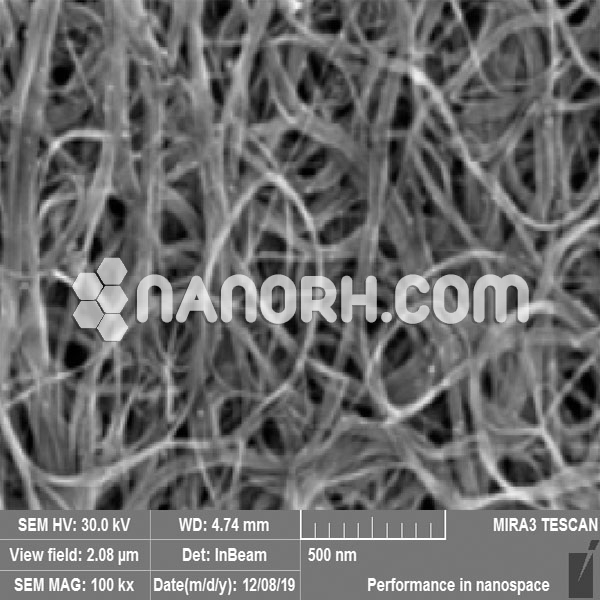

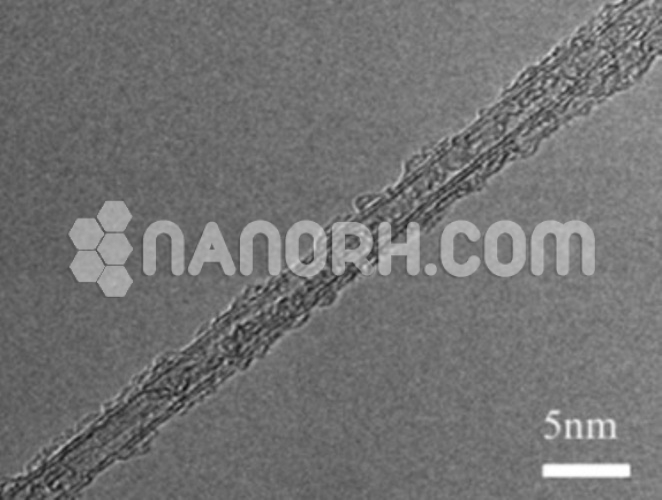

| Average Diameter | >55 nm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | > 60 m2/g (BET) |

| Tap Density | 0.12 g/cm3 |

| True Density | 2.1 g/cm3 |

| Electric Conductivity | >100 s/cm |

Silicon Graphene Carbon Nanotubes Water Dispersion

Introduction

Introduction

Silicon Graphene Carbon Nanotubes Water Dispersion refers to a stable colloidal mixture where silicon nanoparticles, graphene, and carbon nanotubes (CNTs) are dispersed in water. This dispersion harnesses the unique properties of each component—silicon’s semiconductor properties, graphene’s high electrical and thermal conductivity, and carbon nanotubes’ mechanical strength—and brings them into a liquid suspension form, facilitating their incorporation into various applications.

Applications

Energy Storage Systems

Lithium-Ion and Sodium-Ion Batteries: The water dispersion of Si-G-CNTs is used to improve the performance of energy storage devices. In particular, it is an ideal formulation for making anode materials for lithium-ion and sodium-ion batteries. The hybrid material benefits from:

Silicon’s high capacity for lithium or sodium ion storage, improving the overall energy density.

Graphene’s conductivity enhances the rate capability and cycle stability of batteries.

Carbon nanotubes provide structural integrity and reduce mechanical stress during charge and discharge cycles.

Using water dispersion allows these nanomaterials to be effectively integrated into battery electrodes, improving the capacity, charge/discharge efficiency, and long-term stability of batteries used in electric vehicles, portable electronics, and renewable energy storage.

Supercapacitors: Si-G-CNTs in water dispersion are highly useful in supercapacitor electrodes, where rapid charge/discharge and high power density are essential. The dispersion allows the efficient incorporation of these nanomaterials into electrode formulations, improving the energy density and cycling stability of supercapacitors, making them suitable for hybrid energy systems, electric vehicles, and grid storage.

Electronics and Conductive Inks

Conductive Inks and Printing: One of the most important applications of a water-based dispersion of Si-G-CNTs is in the development of conductive inks for printed electronics. The dispersion enables the printing of flexible circuits, sensors, and displays on a variety of substrates, including plastics and paper.

Graphene and carbon nanotubes impart high electrical conductivity, while silicon can enhance the performance of printed components in terms of semiconductor properties.

These inks can be used in the large-scale production of affordable electronics, RFID tags, biosensors, and printed batteries for wearable electronics, smart packaging, and automotive sensors.

Flexible Electronics: The Si-G-CNT water dispersion is also beneficial in flexible and wearable electronics. The dispersion can be directly applied to substrates such as conductive fabrics, plastic sheets, and stretchable films to create stretchable circuits, sensors, and antennas.