| Tetraethyl Silicate | |

| Product No | NRE-30036 |

| CAS | 78-10-4 |

| Purity | 99.9% |

| APS | <10 µm (can be customized) |

| Formula | SiC8H20O4 |

| Molecular Weight | 208.33 g mol−1 |

| Density | 0.933 g/mL at 20 °C |

| Color | NA |

| Melting Point | 168 to 169 °C |

| Boiling Point | NA |

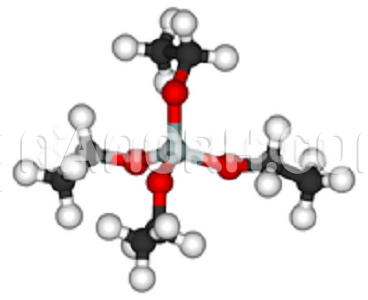

Tetraethyl Silicate

Tetraethyl Silicate

Tetraethyl silicate (TES) is a versatile compound used in various applications across different industries due to its properties as a precursor for silica and silicon-based materials. Here are some key applications of tetraethyl silicate:

Sol-Gel Process:

Silica Gel Production: TES is a primary precursor in the sol-gel process, which involves hydrolysis and condensation to form silica gels. These gels are used in applications such as adsorbents, chromatographic supports, and catalyst carriers.

Silica Coatings and Thin Films: TES is used to create silica-based coatings and thin films that provide properties like enhanced durability, water repellency, and scratch resistance. These coatings are applied to glass, ceramics, and other substrates.

Ceramic and Glass Manufacturing:

Advanced Ceramics: TES contributes to the production of high-performance ceramics by forming silica networks that improve the material’s strength and stability.

Specialty Glasses: Used in the production of optical and specialty glasses where high-purity silica is required for precise optical properties and performance.

Catalysis:

Catalyst Supports: TES-derived silica materials are utilized as supports for catalysts in various chemical reactions, particularly in the petrochemical and pharmaceutical industries. The porous nature of the silica enhances the efficiency of catalytic processes.

Chemical Synthesis:

Silicon-Based Compounds: TES is a precursor for the synthesis of various silicon-based compounds, including silicones and silanes, which are used in a wide range of applications, from sealants to coatings.

Hydrophobic Coatings:

Surface Treatment: TES is used to create hydrophobic (water-repellent) coatings on surfaces. These coatings are applied to materials like textiles, metals, and glass to improve their resistance to water, dirt, and other contaminants.

Concrete and Cement:

Additives: TES is used as an additive in concrete and cement formulations to enhance their mechanical properties and durability. It helps in creating high-performance concretes with improved strength and resistance to environmental factors.

Semiconductor Industry:

Dielectric Films: TES is used in the deposition of silicon dioxide (SiO₂) films, which serve as dielectric layers in semiconductor devices and integrated circuits.

Optics and Photonics:

Optical Coatings: TES is used to produce high-quality optical coatings that are applied to lenses, mirrors, and other optical components to enhance their performance and durability.

Surface Functionalization:

Functionalized Surfaces: TES can be used to modify the surface properties of materials, improving their interaction with other substances or altering their chemical reactivity.