| Titanium Aluminide Alloy Nanopowder | |

| Product No | NRE-2052 |

| CAS No. | 12004-78-3 |

| Formula | TiAl3 |

| Molecular Weight | 128.8 g/mol |

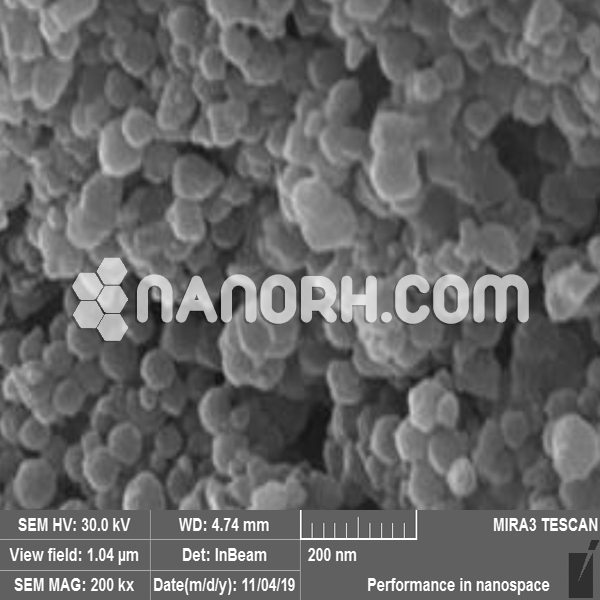

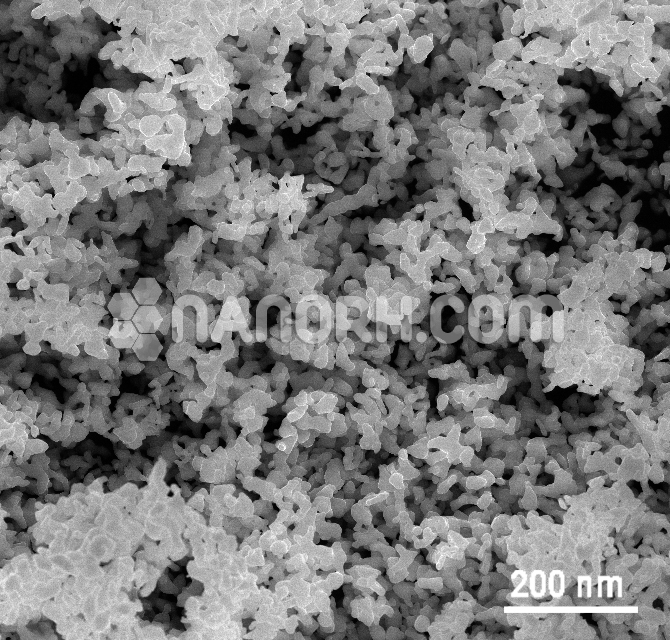

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Density | NA |

| Color | Gray |

| Melting Point | NA |

| Boiling Point | NA |

Titanium Aluminide Alloy Nanopowder

TiAl3 Nanopowder are attractive for high temperature applications, particularly in the aerospace industry, because of their high specific strength and modulus retention combined with good oxidation and creep resistance at elevated temperature. However, the low ductility and fracture toughness, as well as limited shaping and forming ability, has hindered the widespread application of these materials. Attempts at improving the ductility of TiAl3 Nanopowder have been made, including ternary and multielement alloying and grain refinement.The synthesis of nanocrystalline materials has provided further avenues for improving the mechanical properties of metals. Various methods have been applied to produce TiAl3 Nanopowder, such as consolidation of nanopowder, crystallisation of amorphous solids, ball milling or mechanical alloying and severe plastic deformation among which consolidation of nanopowder is believed to be most suitable for industrial application since it is possible to produce bulk samples and final components by near net shape forming. On the other hand, recent three-dimensional printing technology provides a promising method for fabrication of metallic components with complex shapes, by laser melting of the alloy powders. Obviously, as the starting material for both applications, the particle size, phase and composition of alloy powders are key factors determining the microstructure and properties of final products. Hereby, controlled formation of TiAl3 Nanopowder at an industrial scale is of crucial importance for both applications.