| Titanium Aluminium Alloy Sputtering Target | |

| Product No | NRE-43156 |

| CAS No. | 12003-96-2 |

| Formula | Ti-Al |

| Molecular Weight | 74.848 g/mol |

| Purity | 99.99% |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

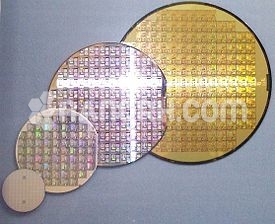

Titanium Aluminium Alloy Sputtering Target

Introduction:

Titanium aluminium alloy sputtering target alloys are intermetallic compounds known for their excellent mechanical properties, low density, and high-temperature resistance. These alloys combine the strengths of titanium and aluminium, making them suitable for a variety of advanced applications. Titanium aluminium sputtering targets are used to create thin films that benefit from the unique properties of the alloy, and sputtering is an effective method for depositing these films with precise control over their composition and thickness.

Applications

Aerospace Components:

TiAl alloys are widely used in aerospace applications due to their high strength-to-weight ratio and excellent high-temperature performance. They are often used in turbine components and structural parts.

Automotive Industry:

In the automotive sector, TiAl is utilized for components requiring lightweight materials with high strength, contributing to improved fuel efficiency and performance.

Thin-Film Coatings:

titanium aluminium films are applied as coatings to improve surface hardness, wear resistance, and corrosion resistance on various substrates, including cutting tools and machinery components.

Electronics:

TiAl alloys can be used in the fabrication of thin-film transistors (TFTs) and other electronic components, where their electrical and thermal properties enhance device performance.

Biomedical Applications:

The biocompatibility of titanium makes TiAl alloys suitable for medical implants and devices, where durability and resistance to corrosion are critical.

Optical Devices:

Titanium aluminium thin films can be utilized in optical coatings, providing anti-reflective properties and enhancing the performance of lenses and mirrors.

Sputtering Process

The sputtering process for titanium aluminium involves using a TiAl target in a vacuum chamber. Energetic ions bombard the target, dislodging atoms that deposit onto a substrate to form a thin film.