|

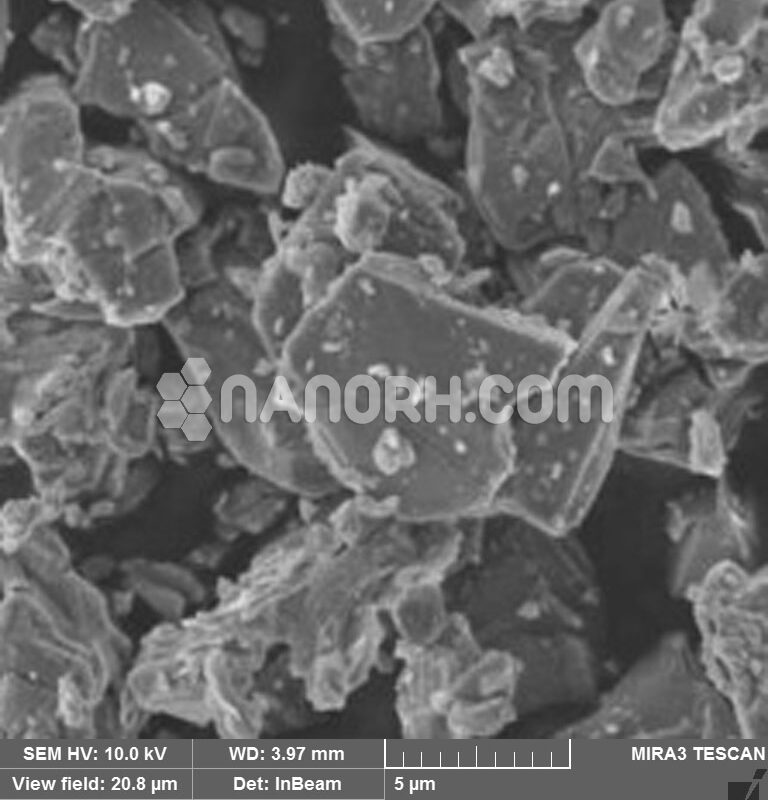

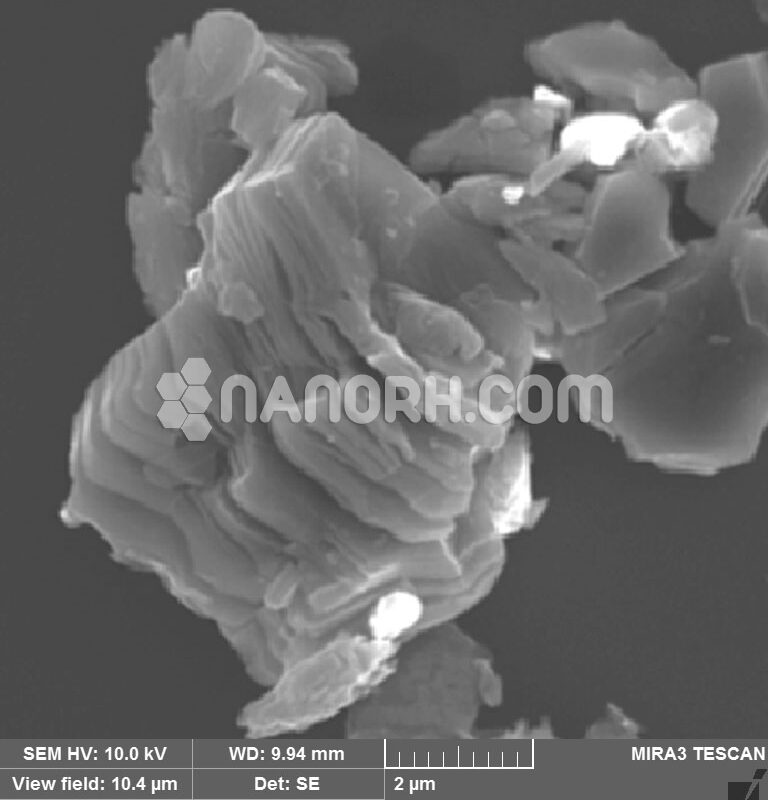

Titanium Aluminum Nitride MAX Phase Powder |

|

| Product No. | NRE-58014 |

| CAS No. | 60317-94-4 |

| Formula | TiAlN |

| Molecular Weight | 88.85 g/mol |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

Titanium Aluminum Nitride MAX Phase Powder

Titanium Aluminum Nitride (TiAlN) is a MAX phase compound with promising properties for various applications due to its combination of hardness, thermal stability, and corrosion resistance. Here are some specific areas where Titanium Aluminum Nitride MAX phase powder can be effectively utilized:

Cutting Tools and Abrasives

Coatings for Tool Bits: TiAlN is commonly used as a coating for cutting tools such as drills, end mills, and inserts. Its high hardness and thermal stability make it ideal for machining hard materials, improving tool life and performance.

Wear-Resistant Layers: The material’s wear resistance also makes it suitable for use in abrasive tools and grinding applications.

High-Temperature Coatings

Protective Coatings: TiAlN can be used as a protective coating for components exposed to high temperatures, such as turbine blades, engine parts, and other aerospace components. Its thermal stability helps in maintaining performance under extreme heat.

Thermal Barrier Coatings

Heat Resistance: TiAlN is effective as a thermal barrier coating, helping to protect substrates from thermal damage. This makes it suitable for applications where high temperatures and thermal cycling are a concern.

Electrical Contacts and Conductors

Electrode Materials: TiAlN’s electrical conductivity can be beneficial in the manufacturing of electrical contacts and electrodes, where efficient electrical transfer and resistance to oxidation are important.

Nuclear and Aerospace Applications

Structural Components: Due to its stability and resistance to radiation, TiAlN can be used in high-performance nuclear and aerospace applications, such as reactor components and spacecraft parts.

Additive Manufacturing

Powder for 3D Printing: TiAlN can be utilized as a powder in additive manufacturing processes, where its properties contribute to the durability and performance of 3D-printed components.

Corrosion-Resistant Coatings

Chemical Resistance: The corrosion resistance of TiAlN makes it suitable for coatings in chemically aggressive environments, including parts exposed to acids and other corrosive substances.

Semiconductor Industry

Thin Films: In semiconductor processing, TiAlN is used as a thin film material due to its hardness and thermal stability, which are important for processes involving high temperatures and abrasive conditions.