|

Titanium Germanium Carbide MAX Phase Powder |

|

| Product No. | NRE-58022 |

| CAS No. | NA |

| Formula | Ti3GeC2 |

| Molecular Weight | 240.26 g/mol |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

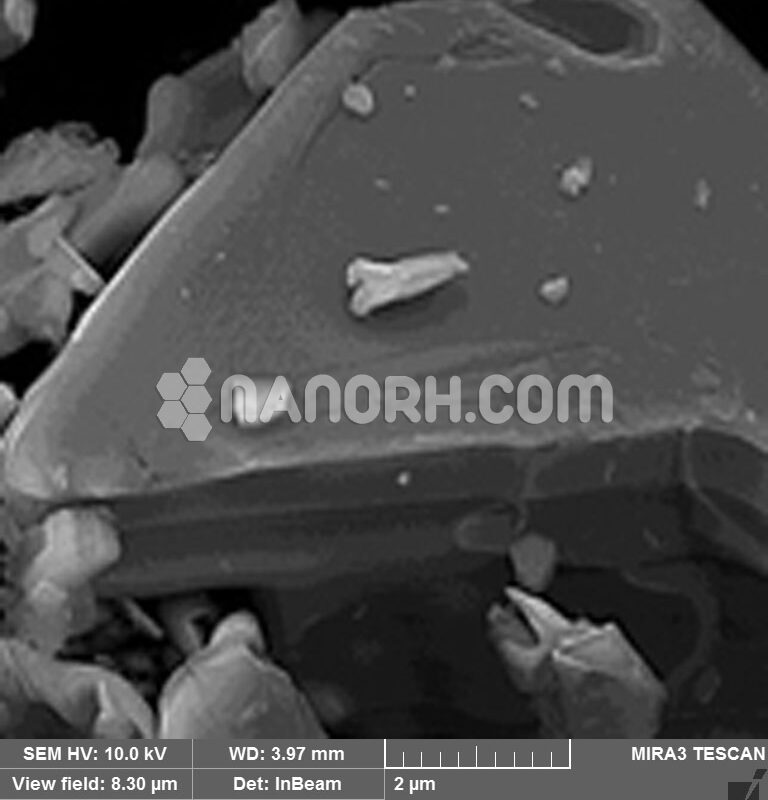

Titanium Germanium Carbide MAX Phase Powder

Titanium Germanium Carbide (Ti3GeC2) is a member of the MAX phases, a family of ternary carbides and nitrides that are known for their unique combination of properties such as high thermal and electrical conductivity, high hardness, and good thermal shock resistance. These materials are generally of interest in a variety of high-performance applications. Here are some areas where Titanium Germanium Carbide might be applied:

High-Temperature Environments: MAX phases are known for their stability at high temperatures. Ti3GeC2 with its high melting point and thermal stability, could be used in environments where extreme heat is a factor, such as in aerospace components, furnace linings, or high-temperature reactors.

Wear-Resistant Coatings: The hardness and thermal stability of Ti3GeC2 make it a good candidate for wear-resistant coatings. These coatings can be applied to tools and components that experience significant wear and tear, such as cutting tools, mining equipment, or mechanical parts in industrial machinery.

Electrical and Thermal Conductors: The high electrical and thermal conductivity of Ti3GeC2 makes it useful in applications requiring efficient heat dissipation or electrical conduction. This includes components in electronics, such as heat sinks or electrodes, where efficient thermal management is crucial.

Structural Components: The combination of strength, thermal stability, and toughness in Ti3GeC2 could be leveraged in structural components that need to withstand high stresses and temperatures, such as in high-performance engines or structural elements in space missions.

Nuclear Applications: The stability and durability of Ti3GeC2 may also be beneficial in nuclear applications, where materials are exposed to radiation and extreme environments. Its properties could be advantageous for use in reactor components or other nuclear-related technologies.

Cutting and Drilling Tools: Due to its hardness, Ti3GeC2 can be used to create high-performance cutting and drilling tools that need to maintain their edge and resist deformation under high stress.

In each of these applications, the specific benefits of Titanium Germanium Carbide would be leveraged to improve performance, longevity, and reliability of the end products.