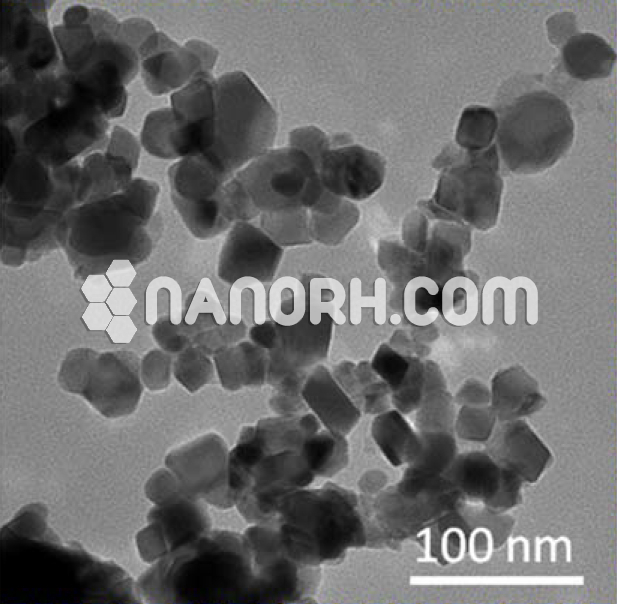

Titanium Oxide (TiO2) Nanoparticles / Nanopowder (TiO2 Anatase HighPurity 99.98% 30nm)

Titanium Dioxide Nanoparticles

| Titanium Dioxide Nanoparticles | |

| Product No | NRE-3061 |

| CAS No. | 13463-67-7 |

| Formula | TiO2 |

| APS | <30nm (Can be Customized) |

| Purity | 99.98% |

| Color | white |

| Molecular Weight | 79.866 g/mol |

| Density | 3.78 g/cm3 |

| Melting Point | 1,843 °C |

| Boiling Point | 2,972 °C |

Titanium Dioxide Nanoparticles (TiO2) Application:

1. UV-resistant material, chemical fiber, plastics, printing ink, coating;

2. Photocatalyst, self-cleaning glass, self-cleaning ceramics, antibacterial material, air purification, sewage treatment, chemical industry;

3. Cosmetics, sunscreen cream, natural white moisture protection cream, beauty and whitening cream, morning and night cream, moistening refresher, vanishing cream, skin protecting cream, face washing milk, skin milk, powder make-up;

4. Coating, printing ink, plastics, foods packing material;

5. Coating for paper-making industry: used for improving the impressionability and opacity of the paper and used for producing titanium, ferrotitanium alloy, carbide alloy etc in the metallurgical industry; 6. Astronautics industry

Recommended Dosage:

There is a wide range of product application in different fields with a large different amount of dosage, from 0.5 to 8%. In general, the quantity to be added is about 1-3% for sunscreen agent, 3-5% for whitening and moisture preservation, 3-8% for ultraviolet ray resistance and 2.5% for printing ink and coating. The end user shall determine the quantity to be added through testing and make the best dosage choice for the best use.

The titanium dioxide nanoparticles have wide applications, viz., reducing toxicity of dyes and pharmaceutical drugs; waste water treatment; reproduction of silkworm; space applications; food industries; etc., and so have immense industrial importance. The applications of nanoparticles synthesized by biological approach will be advantageous for the industries; environment and agriculture.