| Tungsten Carbide Nanopowder | |

| Product No | NRE-5242 |

| CAS No. | 12070-12-1 |

| Formula | WC |

| APS | <55nm (Can be Customized) |

| Purity | 99.9% |

| Color | Black |

| Molecular Weight | 195.85g/mol |

| Density | 15.6g/cm3 |

| Melting Point | 2785-2830°C |

| Boiling Point | 6000°C |

Tungsten Carbide Nanopowder

Introduction

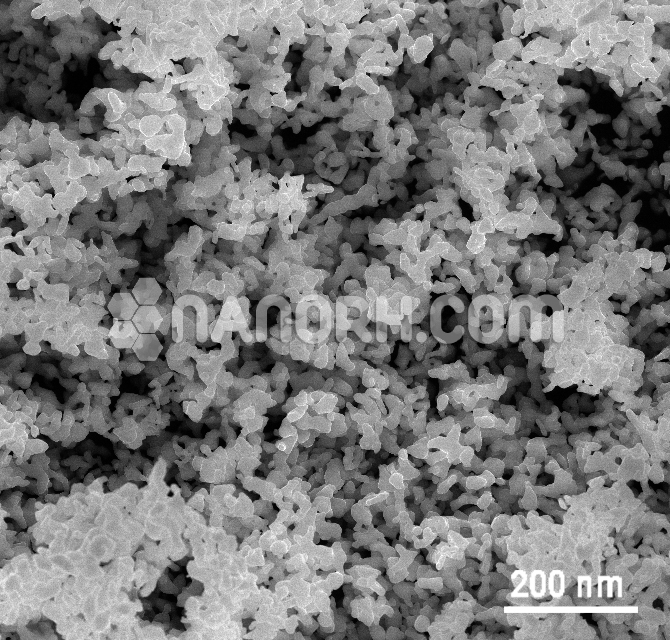

Tungsten carbide nanopowder is a chemical compound made from tungsten and carbon. It is well-known for its remarkable properties, including extreme hardness, high wear resistance, and thermal stability. When in the form of takes on even more exceptional characteristics due to the increased surface area and reactivity of the fine particles. Nanotechnology has enabled the production of WC with particle sizes typically in the range of 1-100 nanometers. These nanoparticles retain all the inherent benefits of bulk while also exhibiting improved performance in many industrial and technological applications.

WC is primarily produced by methods such as chemical vapor deposition (CVD), ball milling, and hydrothermal synthesis, which allow for precise control over the particle size and morphology. The powder is highly sintered to produce compacted, dense materials with excellent mechanical properties, making it ideal for use in industries where durability, strength, and resistance to extreme conditions are critical.

The unique properties of tungsten carbide nanopowder are attributed to the following factors:

High hardness and wear resistance: Tungsten carbide is one of the hardest materials known, surpassing most steels and even many ceramics. As a nanopowder, it can be used in applications that require superior durability and longevity, especially under harsh, abrasive conditions.

Thermal stability: Tungsten carbide nanopowder retains its strength and hardness at very high temperatures, making it an ideal material for high-temperature environments such as those found in aerospace, automotive, and industrial sectors.

Electrical and thermal conductivity: WC nanopowder exhibits good electrical and thermal conductivity, which makes it suitable for various applications in electronics and energy systems.

High surface area: The nano-sized particles possess a large surface area-to-volume ratio, making them more reactive and enhancing their catalytic activity compared to bulk tungsten carbide. This feature makes them ideal for applications in catalysis and energy storage.

Tungsten carbide nanopowder is versatile and can be used as an ingredient in a range of composite materials, coatings, and functional components. It plays a crucial role in advancing technologies related to machining, cutting tools, wear-resistant coatings, energy storage systems, catalysis, and biomedical devices, among others.