| Vanadium Carbide Sputtering Targets | |

| Product No | NRE-43287 |

| CAS No. | 122070-10-9 |

| Formula | VC |

| Molecular Weight | 62.95 |

| Purity | >99.9% |

| Density | 5.77 g/cm3 |

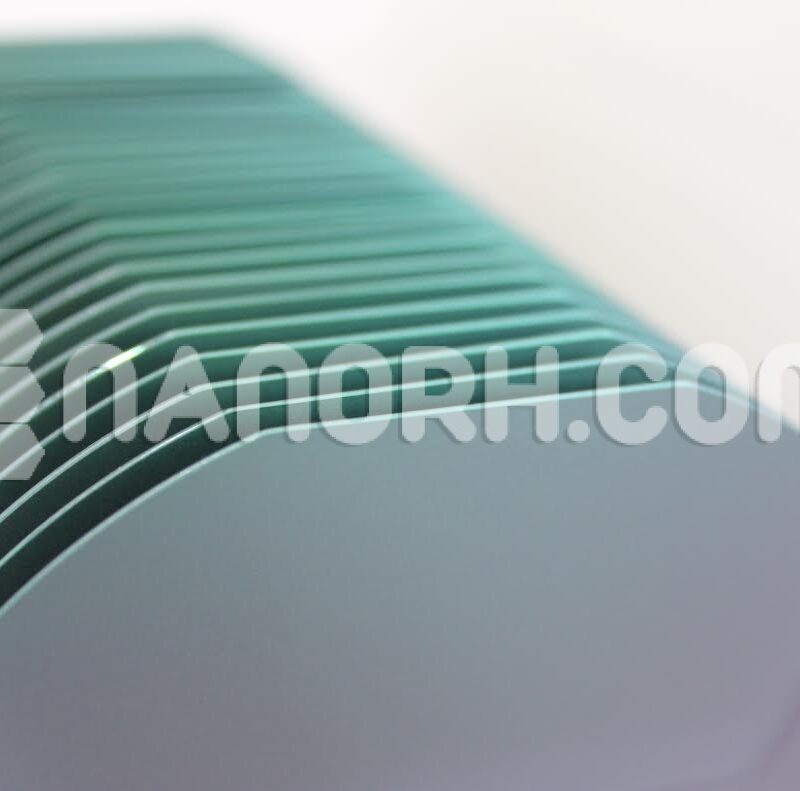

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Vanadium Carbide Sputtering Targets

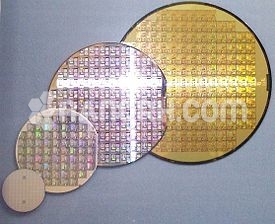

Vanadium carbide sputtering targets commonly used in various industrial applications, particularly in the production of hard coatings and cutting tools. Sputtering targets made from vanadium carbide are utilized in physical vapor deposition (PVD) processes to create thin films with tailored properties, making them valuable in advanced manufacturing and technology sectors.

Applications:

Hard Coatings: VC is widely used to produce hard coatings for cutting tools, drills, and industrial machinery. Its outstanding hardness and wear resistance enhance the durability and performance of these tools, making them suitable for machining hard materials.

Wear-Resistant Films: Vanadium carbide coatings are applied to various components that require enhanced abrasion resistance, such as automotive parts and aerospace components, where longevity and reliability are critical.

Electrical Contacts: Due to its conductive properties, vanadium carbide can be used in the fabrication of electrical contacts and connectors, ensuring reliable performance in electronic applications.

Thermal Barrier Coatings: Vanadium carbide’s high thermal stability allows it to serve as a thermal barrier in high-temperature applications, protecting substrates from heat damage.

Research and Development: VC sputtering targets are utilized in laboratories for research on new materials and technologies, including studies on superconductors and advanced ceramics.

Cutting Tool Inserts: VC is often used in the manufacture of cutting tool inserts, where its hardness and toughness contribute to improved cutting performance.