| Zirconium Silicate Nanoparticles | |

| Product No | NRE-5285 |

| CAS No. | 10101-52-7 |

| Formula | ZrSiO4 |

| Density | 4.56 g/cm³ |

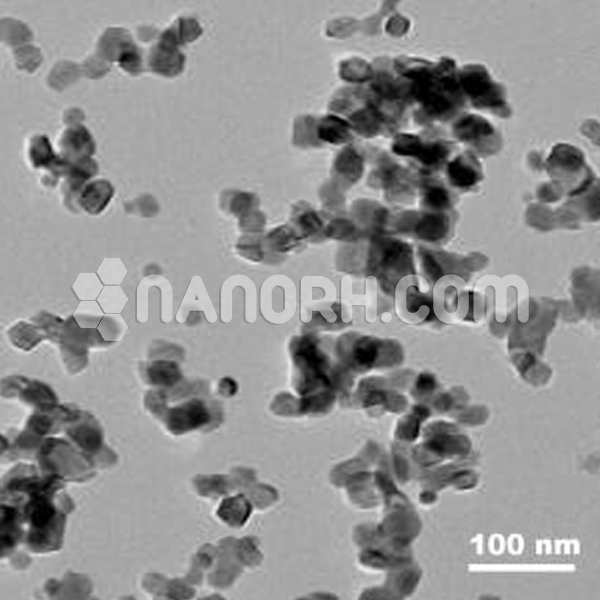

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Form | Powder |

| Molecular Weight | 183.31 g/mol |

Zirconium silicate Nanoparticles

Introduction

Zirconium silicate (ZrSiO₄) is an inorganic compound that consists of zirconium, silicon, and oxygen. In its nanoparticle form, zirconium silicate exhibits enhanced properties compared to its bulk counterpart, including a significantly increased surface area, reactivity, and improved mechanical characteristics. The unique characteristics of zirconium silicate nanoparticles, including their high thermal stability, resistance to wear, and chemical inertness, make them attractive for use in various industrial, environmental, and technological applications.

Zirconium silicate nanoparticles are typically synthesized using methods such as sol-gel processes, precipitation, or hydrothermal synthesis. The result is a fine powder with a nanoscale particle size, which exhibits superior properties such as enhanced strength, lightness, and higher reactivity compared to larger particles.

Properties of Zirconium Silicate Nanoparticles

High Surface Area:

Due to their nanoscale size, zirconium silicate nanoparticles have a high surface area relative to their volume, making them highly reactive. This increased surface area is beneficial in applications like catalysis, adsorption, and surface coatings.

Thermal Stability:

ZrSiO₄ has a high melting point (around 2,550°C), which ensures that the nanoparticles maintain stability at elevated temperatures, making them suitable for use in high-temperature environments.

Chemical Inertness:

Zirconium silicate is chemically stable and inert to many acids and bases, making it resistant to corrosion and degradation in harsh chemical environments.

Mechanical Strength:

The nanoparticles of ZrSiO₄ exhibit enhanced mechanical strength, providing wear resistance, which is crucial for applications that require durability and long service life.

Low Toxicity and Biocompatibility:

Zirconium silicate is relatively non-toxic and biocompatible, which opens up potential applications in biomedical fields, such as drug delivery or implants.