Titanium Vanadium Aluminum Carbide MAX Phase Powder

Titanium Vanadium Aluminum Carbide MAX Phase Powder

|

Titanium Vanadium Aluminum Carbide MAX Phase Powder |

|

| Product No. | NRE-58018 |

| CAS No. | NA |

| Formula | TiVAlC |

| Molecular Weight | 137.80 g/mol |

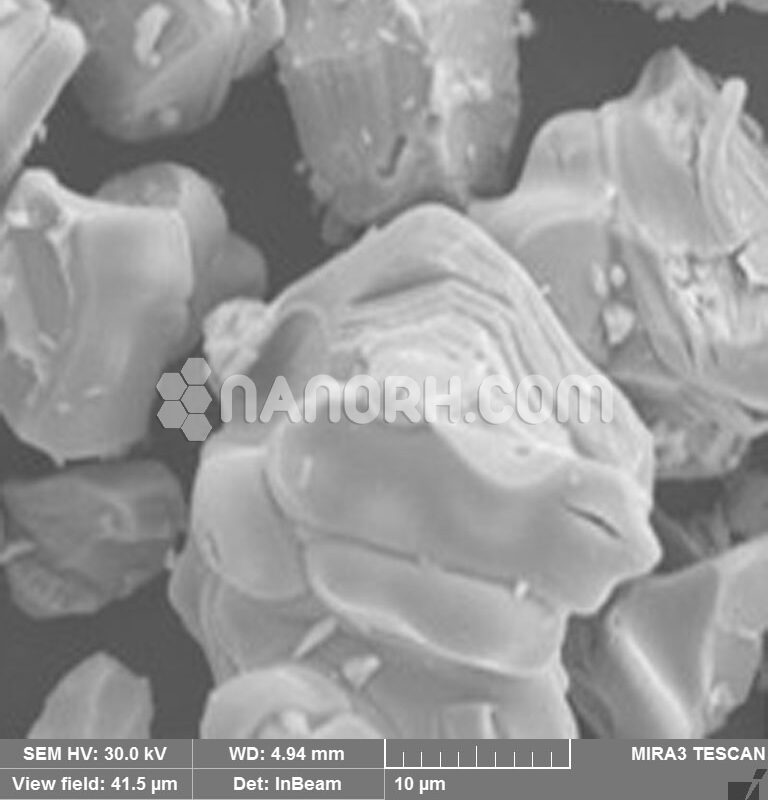

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

Titanium Vanadium Aluminum Carbide MAX Phase Powder

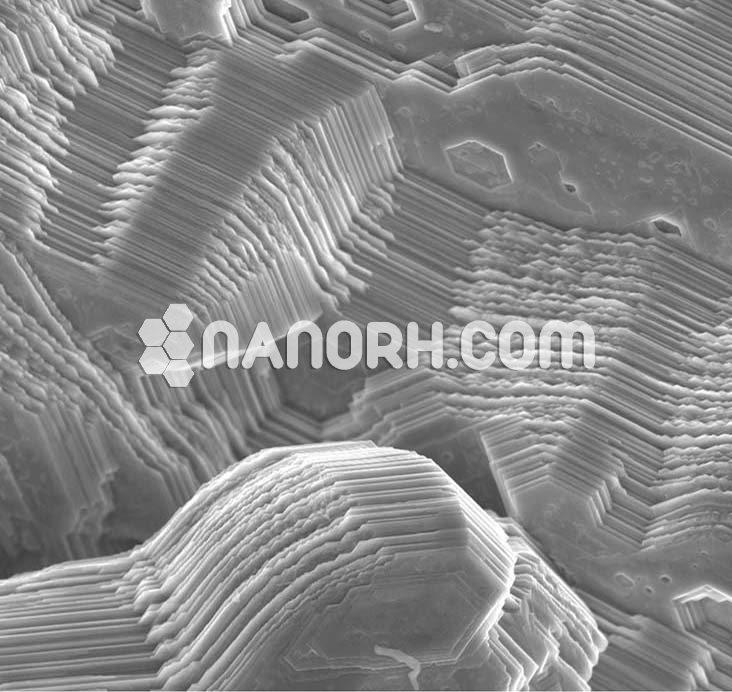

Titanium Vanadium Aluminum Carbide (TiVAlC) is a member of the MAX phase family with unique properties due to the combination of titanium, vanadium, and aluminum. The MAX phases are known for their distinct blend of metallic and ceramic characteristics, such as high thermal and electrical conductivity, good machinability, and high thermal stability.

High-Temperature Components: TiVAlC can withstand high temperatures, making it suitable for use in aerospace and automotive components that operate under extreme conditions. Applications include turbine blades, engine parts, and exhaust systems.

Wear-Resistant Coatings: The hardness and wear resistance of TiVAlC make it a good candidate for protective coatings on tools and machinery. This includes cutting tools, drilling bits, and other components subjected to high friction and wear.

Thermal Management: With its high thermal conductivity, TiVAlC can be used in heat sinks and other thermal management applications. It is effective in dissipating heat in electronic devices, power electronics, and high-performance computing systems.

Electrical Contacts and Conductors: TiVAlC good electrical conductivity makes it useful in electrical contacts, electrodes, and other components where efficient electrical conduction is essential. This includes applications in electrical circuits and energy storage devices.

Nuclear Applications: The stability and robustness of TiVAlC could be beneficial in nuclear reactors and other high-radiation environments. Its properties may enhance the performance and longevity of reactor components and other nuclear-related equipment.

Cutting and Drilling Tools: TiVAlC hardness and toughness make it suitable for high-performance cutting and drilling tools. These tools can benefit from TiVAlC ability to maintain sharp edges and resist wear under extreme conditions.

Structural Components: TiVAlC can be used in structural components that need to endure high stress and temperatures. This includes parts for high-performance machinery, aerospace structures, and other demanding applications.

Wear-Resistant Surface Coatings: Beyond tools, TiVAlC can be applied as a surface coating on a variety of industrial parts to enhance their resistance to abrasion and corrosion, extending their service life.