| Activated Silica Nanoparticles Hydrophobic | |

| Product No | NRE-10001-1 |

| CAS No. | 7631-86-9 |

| Formula | SiO2 |

| Molecular Weight | 60.08 g/mol |

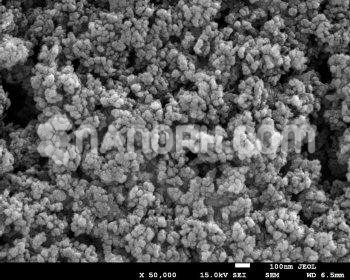

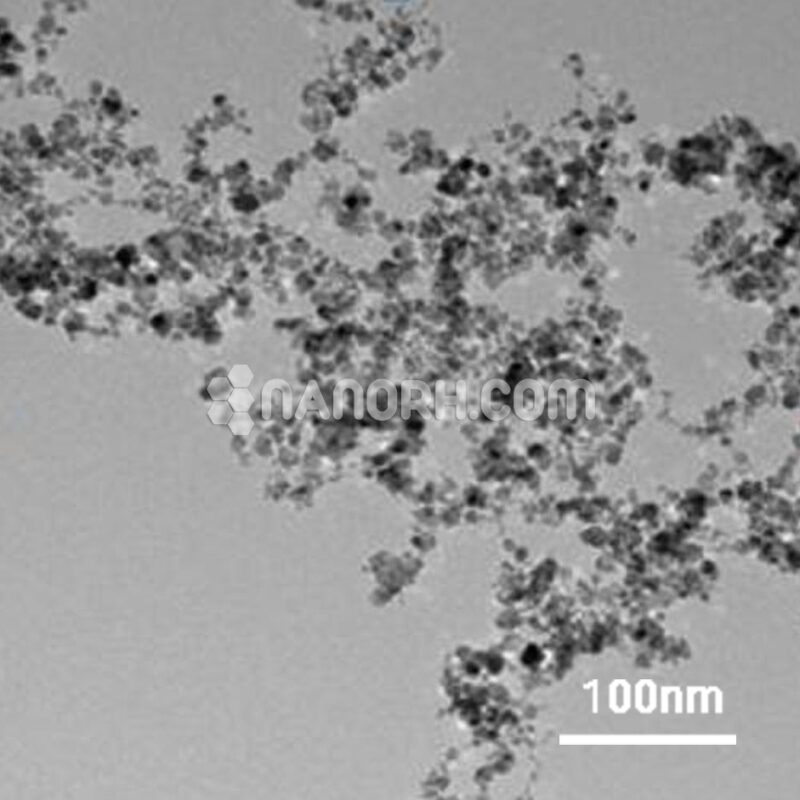

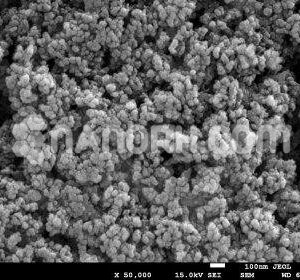

| APS | < 100 nm (Can be Customized) |

| Purity | 99.9% |

| Density | 2.4 g/cm³ |

| Color | White |

| Melting Point | 1713 °C |

| Boiling Point | 2950 °C |

Activated Silica Nanoparticles Hydrofobic Features:

The main application of silica nanoparticles is as an additive for the production of rubber and plastic; as a reinforcing filler for concrete and other construction composites; and as a stable, non-toxic platform for biomedical applications such as drug delivery and theranostics.

Activated Silica Nanoparticles Hydrophobic

Silicon dioxide, also known as silica, silicic acid or any type of silicic acid, is a silicon oxide with the chemical formula SiO2, which is most commonly found in nature such as quartz and in various living organisms. In many parts of the world, silica is the main component of sand. Silica is one of the most complex and abundant families of materials, which exists as a compound of various minerals and as a synthetic product. Examples of note include molten quartz, smoked silica, silica gel, and airgel. It is used in structural materials, in microelectronics (as an electrical insulator) and as components in the food and pharmaceutical industries.

Activated Silicon Oxide Powder

Inhalation of finely divided crystalline silica is toxic and can cause severe inflammation of lung tissue, silicosis, bronchitis, lung cancer and autoimmune systemic diseases, such as lupus and rheumatoid arthritis.

The absorption of amorphous silicon dioxide, in high doses, leads to non-permanent inflammation in the short term, where all effects are cured.

Made by Coupling process – particle surface with functional group, make micro silica work better crosslinking with the resin, greatly Improve adhesion between resin and silicon powder and interfacial hydrophobicity, significantly improve casting body impact strength, reduce sediment, delamination, cracking, increasing the amount of silica powder filling, reduce costs and improve efficiency.