Al2O3 Alumina Spherical Powder / Aluminum Oxide Spherical Powder (Al2O3, alpha, 99.9%)

Al2O3 Alumina Spherical Powder

| Al2O3 Alumina Spherical Powder | |

| Product No | NRE-10002 |

| CAS No. | 1344-28-1 |

| Formula | Al2O3 |

| Molecular Weight | 101.96 g/mol |

| APS | 800nm(can be customized) |

| Purity | 99.9% |

| Density | 3.98g/cm3 |

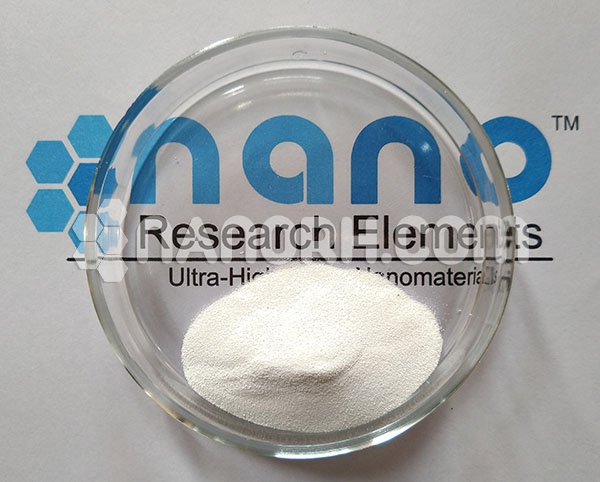

| Color | white |

| Melting Point | 2072 °C |

| Boiling Point | 2977°C |

Al2O3 Alumina Spherical powder / Alpha alumina spherical shape powder, excellent flowability property.

- In integrated circuits

- Transparent ceramic, high pressure sodium lamps and EP-ROM window.

- In YAG laser crystals

- As a cosmetic filler

- Single crystal aluminum garnets, ruby, sapphire, sapphire and yttrium

- High strength ceramic based on alumina and carbon substrates

- Packaging materials, cutting tools, high purity crucible, winding shaft and chimneys.

- Polishing materials, glass products, metal products, semiconductor materials

- Plastic, belt and abrasive belts.

- Wear resistant fittings in advanced paint, rubber, plastic and waterproof materials.

- Catalyst, catalyst support, analytical reagents

- Leading edges of the wings of aerospace aircraft

- Vapor deposition materials, special glasses, fluorescent materials, composite materials and resins.

Spherical powder alpha-Al2O3 / spherical powder of alpha-alumina spherical shape, thanks to its high melting point, good thermal stability, good wear resistance, high mechanical strength, good electrical insulation, excellent corrosion resistance, and other characteristics. industry; Spherical alfa alumina powder as rubber and resin filler, the thermal conductivity of the mixture can be greatly increased, the expansion coefficient can be reduced and the strength of the mixture can be increased. The Al2O3 spherical alpha powder can be dispersed uniformly in the organic body and the formation of the more stacked allows obtaining the mixture of high filler, low viscosity, and high thermal conductivity. At the same time, Al2O3 alpha powder can reduce the wear of the mixer, molding machines and types of molds for equipment to prolong the useful life of the types of equipment.

Al2O3 spherical powder/alfa spherical alumina powder Method: high temperature casting process production method