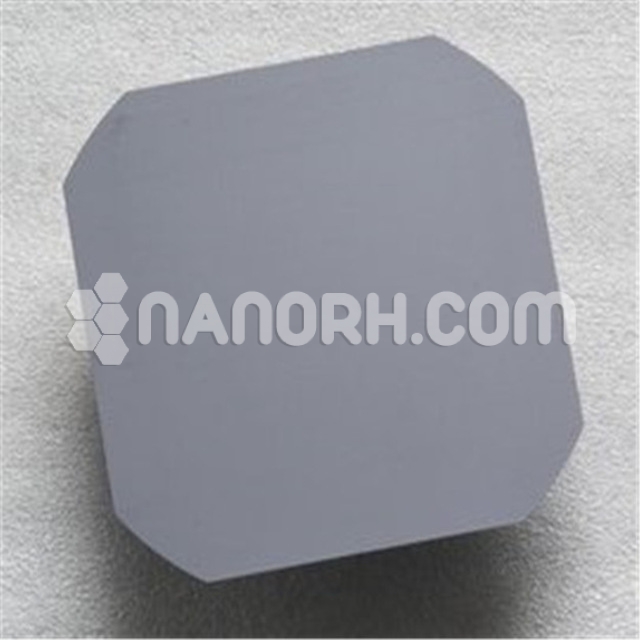

| Aluminium Copper Alloy Sputtering Target | |

| Product No | NRE-43003 |

| CAS No. | NA |

| Formula | AlCu |

| Molecular Weight | NA |

| Purity | 4N, 5N |

| Density | NA |

| Thickness | 3 mm ± 0.5mm(can be customized) |

| Diameter | 50 mm ± 1mm(can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

Aluminium Copper Alloy Sputtering Target

Aluminium Copper Alloy Sputtering Target

Aluminum-copper (Al-Cu) alloy sputtering targets are used in various high-tech and industrial applications where their specific properties offer advantages. Here’s a detailed look at the applications and benefits of using Al-Cu alloy sputtering targets:

Microelectronics and Semiconductor Industry

Application:

Interconnects: Al-Cu alloys are commonly used to deposit thin films for metal interconnects in integrated circuits and semiconductor devices.

Barrier Layers: Used as barrier layers to prevent diffusion between different layers in semiconductor devices.

Why Al-Cu?

Electrical Conductivity: The alloy provides excellent electrical conductivity, which is crucial for efficient signal transmission in microelectronics.

Cost-Effectiveness: Al-Cu alloys offer a balance between cost and performance, making them a popular choice for large-scale semiconductor manufacturing.

Thin Film Deposition for Optical Applications

Application:

Reflective Coatings: Used to create thin films for reflective coatings in optical devices such as mirrors and filters.

Antireflective Coatings: Can be used to reduce reflections and improve light transmission in lenses and optical components.

Why Al-Cu?

Optical Properties: The alloy can be tailored to achieve specific optical properties, such as desired reflectivity.

Durability: Provides a durable coating that maintains its optical performance over time.

Wear-Resistant Coatings

Application:

Tooling and Machinery: Al-Cu coatings are used to enhance the wear resistance of cutting tools, dies, and other machinery components.

Why Al-Cu?

Hardness and Toughness: Copper enhances the hardness and toughness of the coating, improving its wear resistance.

Thermal Conductivity: Copper also improves thermal conductivity, which can be beneficial in applications where heat dissipation is important.

Decorative Coatings

Application:

Consumer Products: Used for decorative finishes on products like electronics, jewellery, and household items.

Why Al-Cu?

Aesthetic Quality: The alloy can produce attractive finishes with good colour and lustre, suitable for decorative purposes.

Corrosion Resistance: Offers better resistance to tarnishing and environmental degradation compared to pure aluminium.

Corrosion-Resistant Coatings

Application:

Aerospace Components: Al-Cu coatings are used on aerospace components to improve their resistance to environmental factors.

Why Al-Cu?

Corrosion Resistance: While aluminium alone provides some corrosion resistance, copper can enhance this property, making the alloy suitable for challenging environments.