| Aluminium Oxide Sputtering Target | |

| Product No | NRE-43005 |

| CAS No. | 1344-28-1 |

| Formula | Al2O3 |

| Molecular Weight | 101.96 g/mol |

| Purity | >99.99% |

| Density | 3.95-4.1 g/cm³ |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

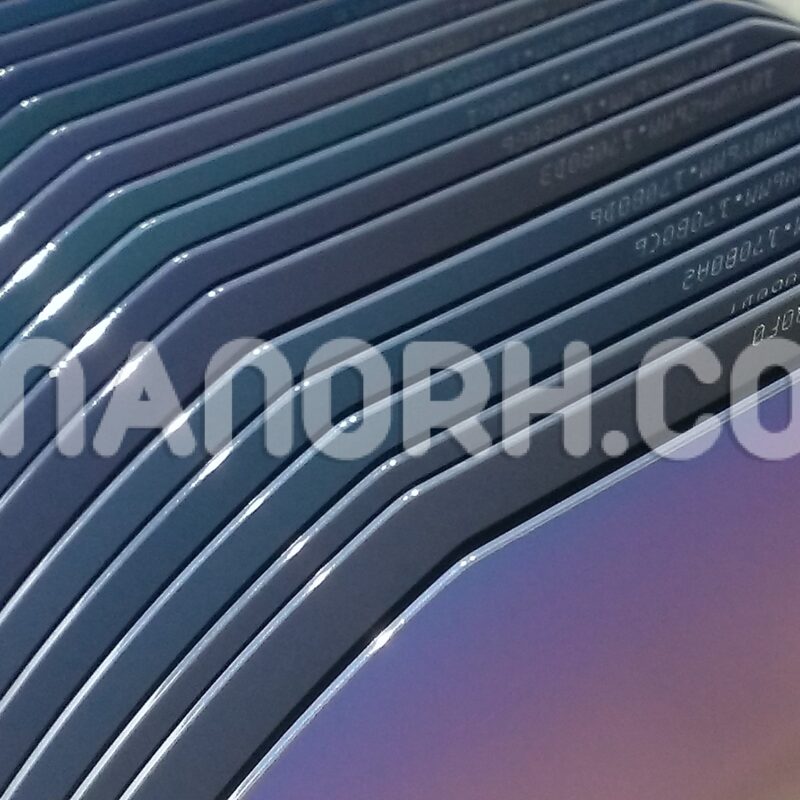

Aluminium Oxide Sputtering Target

Aluminium Oxide Sputtering Target

Aluminium oxide Al2O3 sputtering targets are utilized in various applications due to their unique properties. They are used to create high-quality aluminium oxide films on various substrates through a sputtering process. These targets are valued for their exceptional physical and chemical. Aluminium oxide (Al2O3) sputtering targets are specialized materials used in the sputtering process for thin-film deposition. These targets are crucial in creating high-quality aluminium oxide films for various applications, including electronics, optics, and protective coatings.

Hard Coatings

Application:

Cutting Tools and Machinery: Applied to enhance the hardness and wear resistance of tools, dies, and machinery parts.

Benefits:

Durability: Provides a tough, abrasion-resistant coating that extends the lifespan of tools and machinery.

Dielectric Layers

Application:

Electronics: Used in capacitors, insulators, and other electronic components where electrical insulation is critical.

Benefits:

Electrical Insulation: Offers high dielectric strength and stability, ensuring reliable performance in electronic devices.

Optical Coatings

Application:

Lenses and Mirrors: Used for antireflective and reflective coatings in optical devices.

Benefits:

Optical Clarity: Provides low refractive index coatings that enhance light transmission and reduce reflections.

Protective Coatings

Application:

Aerospace and Automotive Parts: Applied to components exposed to harsh environments and high temperatures.

Benefits:

Corrosion and Wear Resistance: Offers protection against environmental degradation and mechanical wear.

Semiconductor Manufacturing

Application:

Insulating Layers: Used as insulation and barrier layers in semiconductor devices and integrated circuits.

Benefits:

High Dielectric Constant: Ensures reliable electrical insulation and performance in semiconductor applications.

Decorative Coatings

Application:

Consumer Goods and Jewellery: Provides a durable and aesthetically pleasing finish.

Benefits:

Aesthetic Quality: Adds a hard, attractive coating that resists scratching and tarnishing.