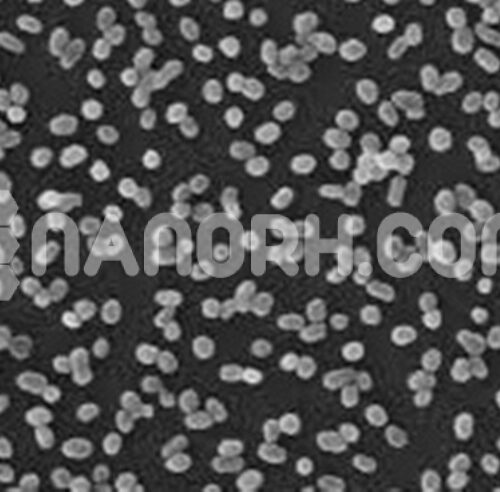

| Aluminium Spherical Powder | |

| Product No | NRE-8001 |

| CAS No. | 7429-90-5 |

| Formula | Al |

| Molecular Weight | 26.982 g/mol |

| APS | <40um (Can be Customized) |

| Purity | 99.9% |

| Color | grey |

| Density | 2.70 g/cm3 |

| Melting Point | 660.32 °C |

| Boiling Point | 2470 °C |

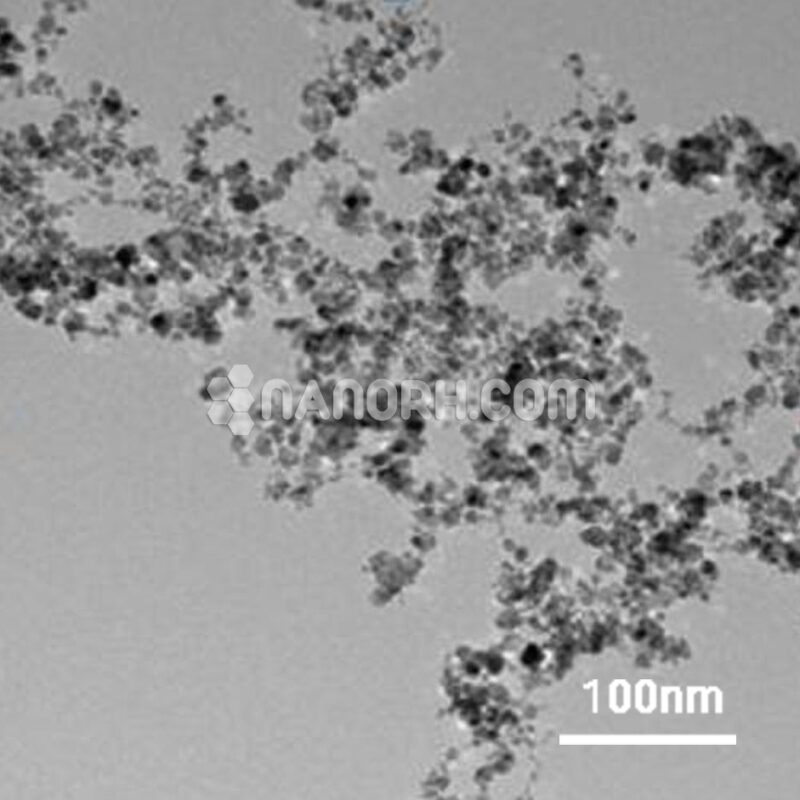

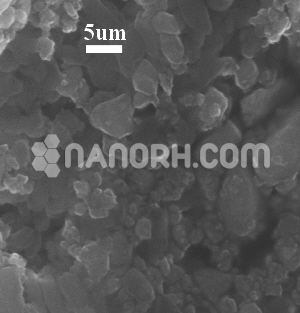

Aluminium spherical powder

Aluminium spherical powder has a wide range of applications across various industries due to its unique properties. These properties include lightweight, high thermal conductivity, corrosion resistance, and good electrical conductivity. Here are some common applications of aluminium spherical powder:

Additive Manufacturing (3D Printing): Aluminum spherical powder is used in additive manufacturing processes like selective laser melting (SLM) and powder bed fusion to create complex and lightweight structures. These components find applications in the aerospace, automotive, and medical industries.

Aerospace: Aluminum spherical powder is used in aerospace applications to create lightweight parts, such as aircraft components and satellite structures. Its high strength-to-weight ratio is particularly advantageous in aerospace.

Automotive: Aluminum powder is used in the automotive industry for manufacturing lightweight parts, such as engine components, suspension systems, and body panels. These components help improve fuel efficiency and reduce emissions.

Pyrotechnics: Aluminum powder is used in fireworks and pyrotechnic displays to produce bright and sparkling effects. It acts as a fuel that burns at high temperatures and emits a brilliant white light.

Paints and Coatings: Aluminum powder is often added to paints, coatings, and inks to provide a metallic or reflective finish. It enhances the aesthetic appeal and can also improve the UV resistance and durability of the coatings.

Thermal Management: Due to its high thermal conductivity, aluminum powder is used in thermal pastes and compounds for heat sinks, electronic components, and LED lighting. It helps dissipate heat efficiently.

Reactive Materials: Aluminum powder can be used in combination with other materials to create reactive composites, such as thermite mixtures used in welding or incendiary devices.

Powder Metallurgy: Aluminum spherical powder can be used in powder metallurgy processes to produce a wide range of components, from simple parts like bushings to complex shapes like gears and pistons.

Fuel Additives: Aluminum powder can be used as a fuel additive in solid rocket propellants and as an energy-dense fuel for certain military applications.

Building Materials: Aluminum powder can be added to construction materials, such as concrete and lightweight panels, to enhance their strength and thermal properties.

Electronics: It is used in electronics manufacturing for applications like printed circuit boards (PCBs) and thermal interface materials to improve heat dissipation.

Chemical Reactions: Aluminum powder is sometimes used as a reducing agent in chemical reactions, such as in the production of certain metals or as a component in metal-based chemical catalysts.

Art and Decoration: Artists and craftsmen use aluminum powder in sculptures, art installations, and decorative items to achieve a metallic or shiny appearance.

Explosives: In certain military and industrial applications, aluminum powder can be used as a component in explosives to enhance their energy and explosive power.