| Aluminum Doped Zinc Oxide Micro Powder | |

| Product No | NRE- 10006 |

| CAS No. | Na |

| Formula | Al2O4Zn |

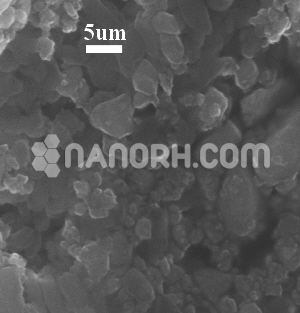

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Color | white |

| Molecular Weight | 183.34 |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

Aluminum Doped Zinc Oxide Micro Powder

AZO micro-powders with exceptional electrical conductivity and photocatalytic activity were synthesized by the co-precipitation method. In order to determine the photocatalytic activity of the synthesized powder, a study on the degradation of methyl orange (MO) in the sun was carried out. It was found that the presence of a small amount of Al can effectively enhance the photocatalytic activity of ZnO during MO degradation. Additionally, the introduction of synthesized AZO micro-powders with excellent electrical conductivity into a polypropylene (PP) polymer matrix is attractive for many engineering applications. To improve dispersion and AZO compatibility with the PP polymer matrix, AZO was initially modified with KH-550 silane coupling agent. Then, the surface-modified AZO particles were encapsulated in polypropylene (PP) by melt-blending. Moreover, we studied the effects of different concentrations of AZO micro-powders, with excellent electrical conductivity, on the electrical conductivity of AZO/PP compounds. Doped ZnO powders revealed similar electrical conductivity to indium tin oxide (ITO); however, they benefit more than ITO because ZnO is non-toxic, non-polluting, thermally stable, and has a lower production cost. Numerous studies have shown that zinc oxide (ZnO) powders doped with different ions exhibit both lower resistivity and higher transmission in the visible range. These properties make them ideal for use in polymeric compounds. Among these dopants, ZnO (AZO) powders doped with aluminum are conductive and transparent in the visible and can therefore be used in transparent conductive compounds. Many techniques have been developed to synthesize AZO, such as solvothermal method, sol-gel method, thermal evaporation method, vapor deposition method, pulsed laser deposition method, magnetron sputtering and the coprecipitation method. Compared to the above methods, co-precipitation has received much attention as it is a feasible, more reproducible, economical and environmentally friendly process.