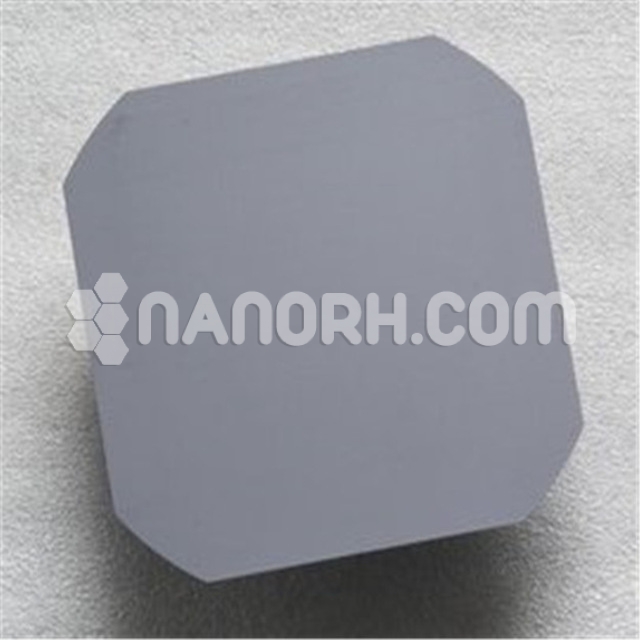

| Aluminum Fluoride Sputtering Targets | |

| Product No | NRE-43310 |

| CAS No. | 7784-18-1 |

| Formula | AlF3 |

| Molecular Weight | 83.98 |

| Purity | >99.9% |

| Density | 2.88 g/cm3 |

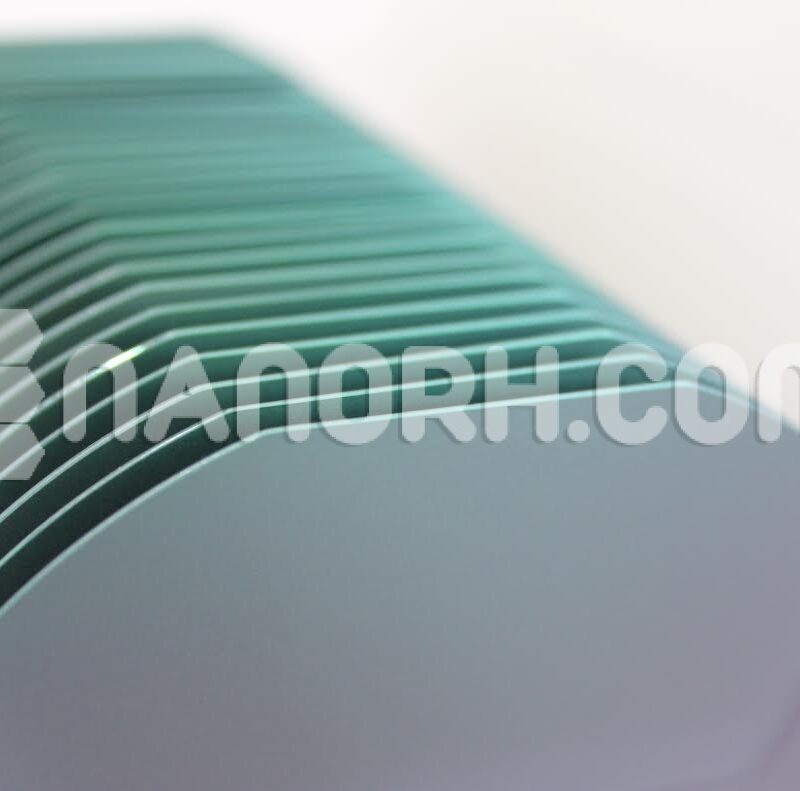

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Aluminum Fluoride Sputtering Targets

Aluminum fluoride (AlF₃) sputtering targets are used to deposit thin films of aluminum fluoride in various applications due to their unique properties. Here are some common applications:

Optical Coatings

Application: Anti-reflective coatings, optical filters, and lenses.

Benefits: Aluminum fluoride films provide low refractive index coatings that reduce reflection and improve the performance of optical components, enhancing clarity and light transmission.

Anti-Reflective Coatings

Application: Eyeglasses, camera lenses, and displays.

Benefits: AlF₃ coatings are used to reduce glare and improve light transmission in optical devices and consumer products.

Protective Coatings

Application: Corrosion-resistant coatings for various substrates.

Benefits: Aluminum fluoride provides a protective layer that can resist chemical corrosion and extend the life of components in harsh environments.

Dielectric Layers

Application: Capacitors and insulators in electronic devices.

Benefits: Used as dielectric materials due to their insulating properties, aluminum fluoride films improve the performance and reliability of electronic components.

Semiconductor Processing

Application: Etching masks and deposition in semiconductor manufacturing.

Benefits: AlF₃ can be used as an etching mask or in thin film deposition processes, aiding in the creation of precise patterns and structures in semiconductor devices.

Solar Panels

Application: Coatings for photovoltaic cells.

Benefits: Aluminum fluoride coatings can improve the efficiency of solar panels by optimizing light transmission and reducing reflection losses.

Laser Systems

Application: Coatings for laser optics.

Benefits: AlF₃ films are used in laser systems for their low absorption and high durability, enhancing the performance and lifespan of laser optics.

Chemical Vapor Deposition (CVD)

Application: Thin film deposition processes.

Benefits: AlF₃ targets are employed in CVD processes to create thin, uniform films with specific chemical and physical properties for various applications.